These can be rotated into the ground in order to provide nutrients. However, most people that grow rice will have very specific formulas for improving the soil. Therefore, placing rice husks back in the ground may not be the best course of action to take. Instead, you may want to convert this material into a form of burnable charcoal. You can do this when you have access to a rice husk carbonization(maquina para hacer carbon) furnace. One of the top companies in the world that produces these products is Beston.

Why Would You Choose Beston

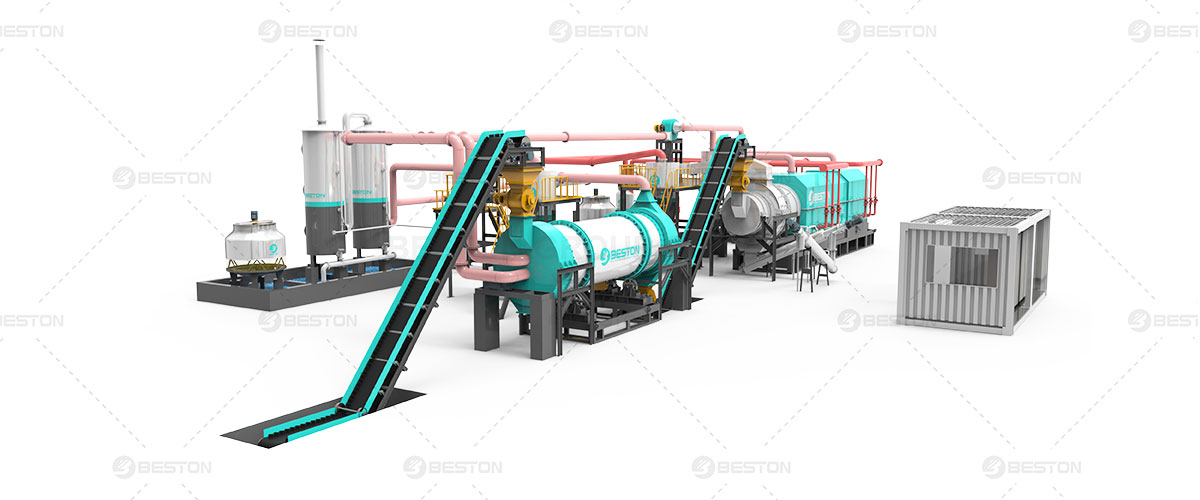

Beston is a very large company that has built a stellar reputation because of the products that they produce related to pyrolysis. They have created many different machines, including a rice husk carbonization furnace, that is capable of producing tons of charcoal and other forms of burnable fuel. You can trust this company which also sells many other products. They are well-known in this industry and many others. They are also a very affordable business that is able to produce their products for less. However, before you make this investment, you should know a little bit more about the process.

What Does A Rice Husk Carbonization Furnace Do?

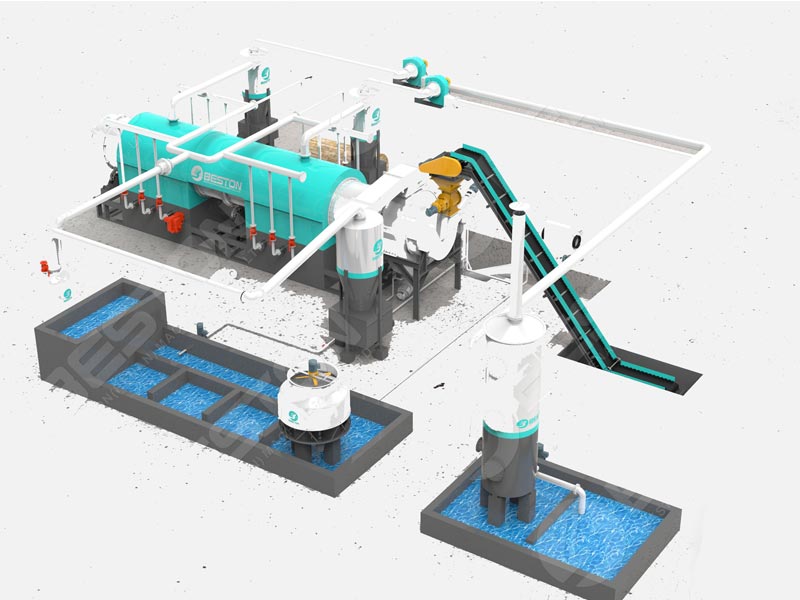

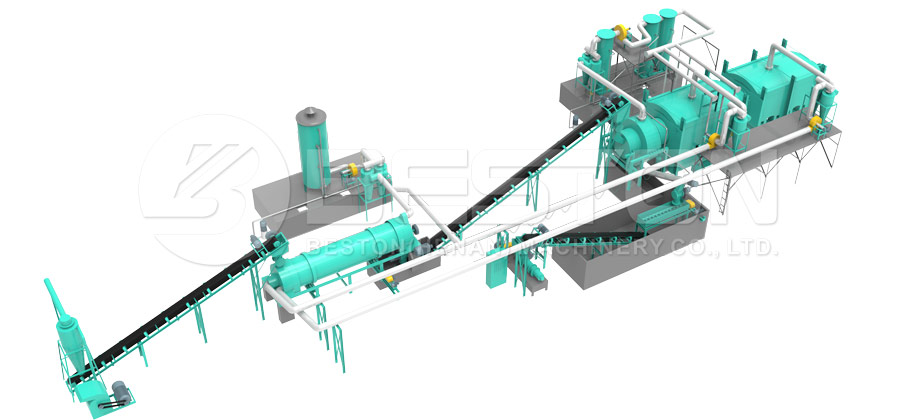

By another name, this is simply a carbonization plant(hornos metálicos para hacer carbón). It could also be a pyrolysis machine if you need something smaller. The term pyrolysis often refers to the process by which heat will activate a change in organic materials, causing them to break down into component parts. The solid parts of this process will lead to the formation of charcoal. There will also be gaseous materials that will solidify into biofuel and oil that you can use. All of these products will be derived directly from rice husks. To do this, you will need to invest in one of their top machines.

How To Obtain One From Beston

A simple call to a representative of this company(BESTON GROUP) will suffice. They can tell you all about the different pyrolysis plants and machines that they currently have in stock. Many of them are large enough to help you convert tons of rice husks that would otherwise go to waste. The larger the unit, the more expensive it is going to be. If you have a small rice farm, you may only need a carbonization machine that is designed for a much smaller amount of output. It is very important to tell them that you are specifically looking for a rice husk carbonization furnace that can help you process every rice husk that you produce.