Would you like to find a resource for ready mix concrete? Perhaps you need more than you can get at a hardware store that you can make yourself. It’s nice to have it brought in, ready to pour, especially if you have everything blocked off for your walkway or driveway and it’s ready to go. There are many companies in cities and towns that provide this type of service, and you can easily find a business that will be willing to work with you. You may have to call several companies to get a price that is affordable, but once you are done, you will be able to get a great deal working with businesses that use ready mix concrete pumps so you can complete your project.

What Are Ready Mix Concrete Pumps?

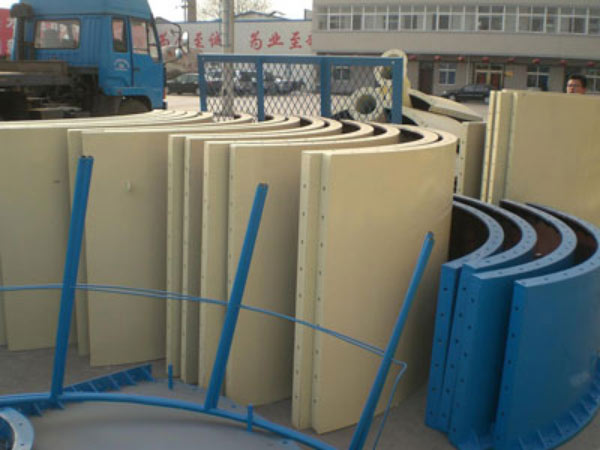

First of all, a concrete pump is a machine that is used for the sole purpose of transferring liquid concrete from one location to the next. There are two types that use these pumping mechanisms, one of which is attached to a truck called a boom concrete pump that is remote-controlled and is used for most large construction projects. The second type will be attached to a trailer or a truck, usually called a line pump. See details here: http://concretemixerpumps.com/line-concrete-pump-for-sale/.

There are a few things that are necessary for this to work including flexible concrete hoses attached to the outlet of the machine, used to distribute the concrete for jobs such as sidewalks, driveways and even swimming pools. Unless you are working in a mine, or a large tunnel, there is a third type called a truck mounted concrete pump that you will probably never see. These have been used for decades, and due to the thick viscous nature of concrete, piston pumps are the main mechanism which push cylinders through a tube valve to distribute the concrete.

Finding A Company To Help You

In most cases, you can find a concrete pump company that has ready mix ready to go. It is the best type of concrete to use if you want to get the job done fast, it is far more efficient than mixing your concrete in a wheelbarrow. Once you have found several companies, your best price is going to come from the business that will quote you the lowest bid. This is typically going to come from a company that uses a line pump or trailer pump for sale because these are the least expensive.

The concrete itself can also vary in price, and this will all be included in the estimate. Make sure that you compare not only the estimate that you receive, but what people are saying about these companies on review sites or the local listings on the web.

Even though you could probably do this type of work on your own, mixing individual bags of concrete is difficult work, and is also very slow. The odds of being able to have a consistent appearance to the concrete, especially with large jobs, is virtually impossible unless you have large quantities of it poured. Instead of waiting several hours to get the job done, these machines can distribute the concrete almost instantly. Than you simply have to smooth it out, and wait for it to set, and your small project will be complete.