Biochar is a highly coveted product by biochar making equipment. It is the result of carbonization. For example, if you are harvesting bamboo, or if you have millions of palm kernel shells each year, these can be converted into biochar or charcoal. This physical residue is something that you should think about producing. If you do have access to biodegradable material, this can be converted quite easily. It can even be done if you have large amounts of rubber tires or plastic bottles. It is a business model that is gaining traction today. These are the many reasons that biochar production equipment for sale can benefit your business significantly.

How Can These Be Used Appropriately?

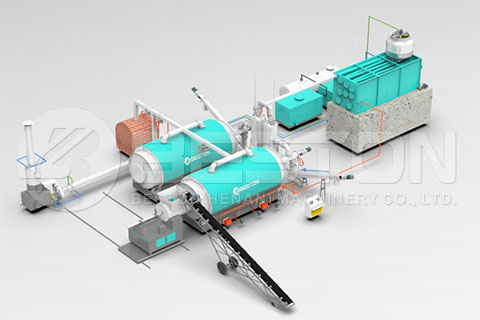

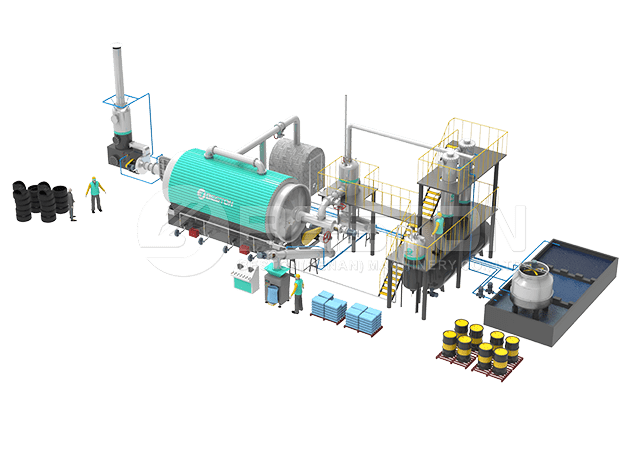

Let’s say that you are the owner of a large sugarcane plant. Perhaps you harvest bamboo, palm oil, or rice. Once you have done this, you are going to have a large amount of organic material that is just sitting there. Over time, it could degrade and decompose into the soil. However, this could be a waste. Instead, you can convert all of this into biochar. This is done using a pyrolysis machine. There are even larger units called pyrolysis reactors that can help you process a substantial amount of material. Besides, the coconut shell charcoal machinery is the same as this machine. Just choose the right model.

Why Could This Be Beneficial For Your Business?

The benefits of using these machines is twofold. First of all, it’s going to save you money. Instead of having to hire someone to get rid of the rice hulls, or the coconut shells, you can instead convert them right away. The process itself can be somewhat comprehensive. You do need to break down all of this into smaller pieces. It must then be shuttled into a pyrolysis reactor and the oxygen must be taken out before it is superheated. It is this excessive amounts of heat, without any oxygen, that allows the carbonization process to occur. The byproduct of all of this will include liquid fuels and a substantial amount of biochar that can be sold. The sawdust charcoal making machine cost depends on the scale you choose.

Do You Need A Large Business To Get Biochar Making Equipment for Sale?

It is not necessary to have a giant business. You may have a medium or small-sized farm or plantation. On you may also have access to rubber tires. Plastic bottles must also be recycled in an appropriate way. Therefore, if you simply have access to any or all of these materials, biochar making equipment will make sense. You could hire people to process all of these for you, allowing you to generate a sizable amount of revenue for your company.