If you own an egg tray manufacturing company, you need to keep up with the rising competition. New companies appear to be sprouting left and right, so you must find ways to continue attracting your target customers, increase productivity, and boost sales. A simple way to do this is to invest in the best equipment that yields the highest returns. In that regard, hardly anything comes close to a fully automatic egg tray machine. This piece of equipment enhances the overall productivity of your company without any additional manpower.

A fully automatic egg tray machine is particularly designed to create egg trays out of waste paper. It’s worth noting that most models can also create egg crates, fruit trays, and coffee cups. Essentially, you’re getting an all-in-one machine that could widen the products your company offers. At the same time, you’re doing the environment a huge favor by preventing waste paper from filling up landfills. Recycling waste paper and converting them into something many people could use every day can have a massive impact on the green movement.

Plenty of waste materials can be used to feed this egg tray maker machine. The list includes corrugated paper, old newspaper, wrapping paper waste notebook paper, and cartons. The common denominator among these materials is that they’re abundantly available. You wouldn’t have any problems sourcing these materials and you can have them for cheap.

It’s also essential to learn about the various sizes of egg trays that these machines can produce. The most common are 1- to 3-dozen egg cartons. But as previously mentioned, these machines can manufacture other types of products such as coffee cup trays, shoe trays, and product packaging. Be sure to check the custom molds you can use for the machine you’re buying.

If you’re operating a large-scale egg tray manufacturing company, it’s recommended to invest in a machine with packaging equipment. Otherwise, one with a pulp making machine, equipment, and drying machine should suffice. You can ger affordable machines with good quality here: https://pulpmouldingmachines.com/egg-tray-manufacturing-machine/.

A fully automatic egg tray machine can set you back quite a bit. But instead of looking at the upfront cost only, you should think about how much value you’re getting for your money. An automatic variant is the most expensive egg tray machine on the market, so don’t be surprised if you’d have to reach deep in your pockets to afford one. It’s not uncommon to see prices that go beyond $50,000. Of course, machines with better specifications and features would cost more.

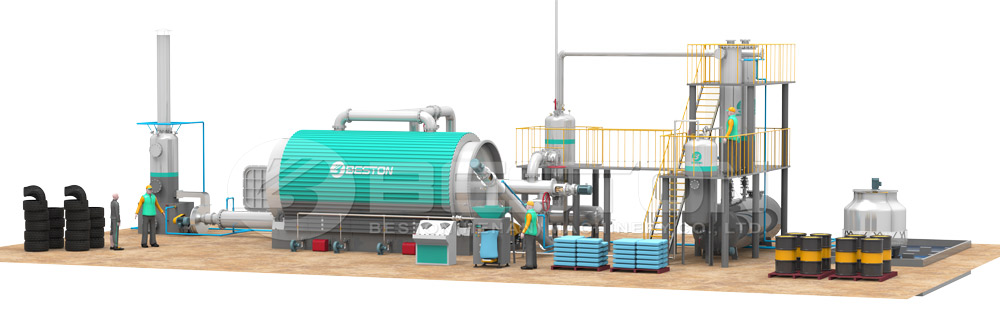

Despite its high upfront cost, an automatic egg tray making machine made by Beston (Henan) Machinery Co., Ltd is well worth the investment. It can radically change the way you go about your daily operations. You might even free up some manpower because this machine allows you to take an almost hands-free approach. Just remember to spend enough time doing your research until you find an equipment that ticks all the boxes.