As global industries pivot toward sustainable production methods, biomass carbonization technologies have gained significant traction. The decision to invest in a charcoal making machine—whether for commercial-scale production or small-scale deployment—requires a clear understanding of operational parameters, cost components, and technology specifications. With multiple configurations available, from biochar making machine units to charcoal briquette making machine systems, selecting the right setup is essential for long-term viability.

Machine Type and Application Scope

Charcoal production equipment comes in various forms, each designed to process specific biomass inputs such as wood chips, coconut shells, rice husks, or sawdust. The biochar making machine focuses on converting biomass into porous, carbon-rich material for use in soil amendment, carbon sequestration, and water filtration. This system prioritizes stable pyrolysis conditions and maximizes biochar yield over combustible gas or tar fractions.

Alternatively, the charcoal briquette making machine is engineered to compress powdered charcoal into uniform briquettes. This equipment is ideal for producers targeting the fuel market, particularly in regions with high demand for clean-burning solid fuels in residential and commercial cooking.

For localized or mobile applications, a small charcoal making machine offers portability and simplicity. Though limited in throughput, these compact systems provide a low-cost entry point into the biomass-to-energy sector, suitable for pilot projects, rural operations, or decentralized waste-to-fuel solutions.

Cost Structure and Capital Investment

Initial investment varies widely based on automation level, reactor size, emission treatment systems, and drying components. Basic models of small charcoal making machine units start from a few thousand dollars, while fully continuous systems with integrated pollution control and high output capacity may require several hundred thousand dollars.

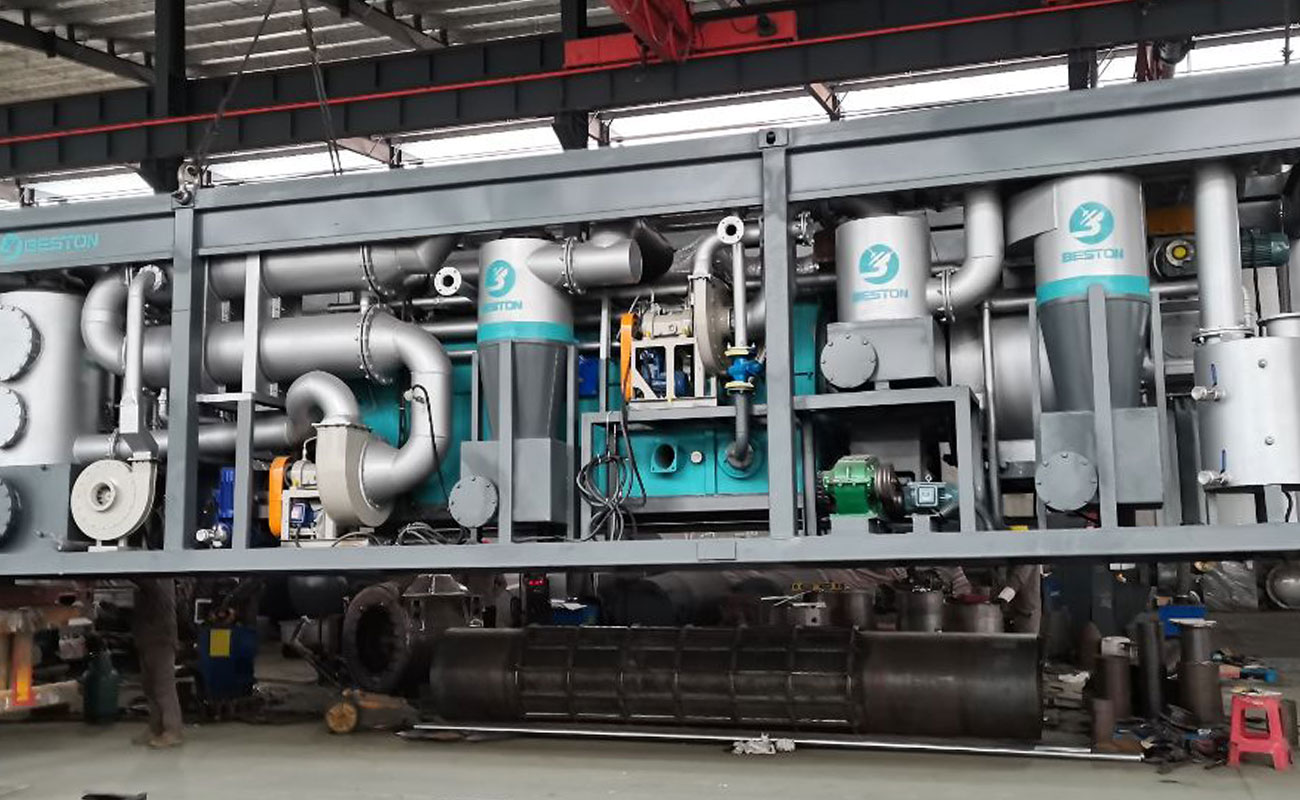

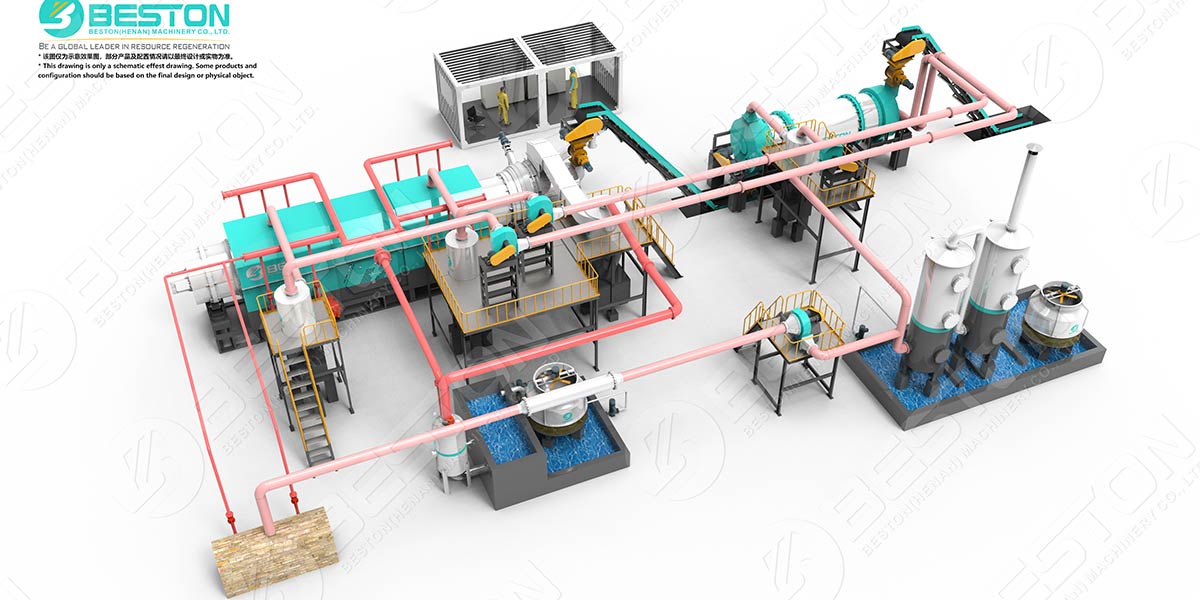

Charcoal making machine manufacturers typically provide pricing structures that reflect customization, material selection (e.g., 304 stainless steel vs. carbon steel), and optional configurations such as condensers, dust removal units, and temperature control systems. Beyond equipment cost, investors should account for auxiliary expenses including:

-

Site preparation and civil work

-

Installation and commissioning

-

Operator training and maintenance

-

Biomass preprocessing equipment (crusher, dryer, etc.)

While capital outlay is considerable for industrial systems, payback periods can be compressed through diversified output utilization—charcoal, bio-oil, and syngas—especially when by-products are sold or reintegrated into onsite energy systems.

Output Capacity and Operational Efficiency

Production capacity typically ranges from 200 kg/h in a small-scale reactor to over 3 tons/h in a fully continuous line. Continuous reactors offer superior thermal efficiency, reduced labor, and higher yield consistency. Intermittent or batch-type machines may suit operations with lower feedstock availability or minimal infrastructure.

Energy self-sufficiency is another critical variable. Modern systems recycle syngas to heat the reactor, significantly reducing external fuel needs and operational cost. Efficiency gains are also realized through integrated heat recovery and exhaust gas treatment.

Manufacturer Credibility and After-Sales Support

The choice of supplier impacts long-term performance and cost management. Reputable charcoal making machine manufacturers offer technical consultation, process customization, and robust after-sales service. Important factors to evaluate include:

-

Proven project references and client case studies

-

Compliance with environmental and safety standards

-

Availability of spare parts and remote diagnostics

-

Support for local certification or import procedures

Conclusion

Investing in a charcoal making machine involves more than equipment acquisition—it demands strategic alignment with biomass availability, market demand, regulatory frameworks, and production goals. Whether opting for a biochar making machine for agronomic use, a charcoal briquette making machine for fuel markets, or a small charcoal making machine for localized applications, informed planning and supplier due diligence are essential to securing operational and financial success.