The thermal desorption unit stands as a cornerstone in the realm of hazardous waste management, offering unparalleled advantages in the recycling of oily hazardous waste. This article meticulously examines the benefits conferred by thermal desorption units, illuminating their pivotal role in sustainable waste remediation efforts.

Understanding Thermal Desorption Technology

Operational Principles

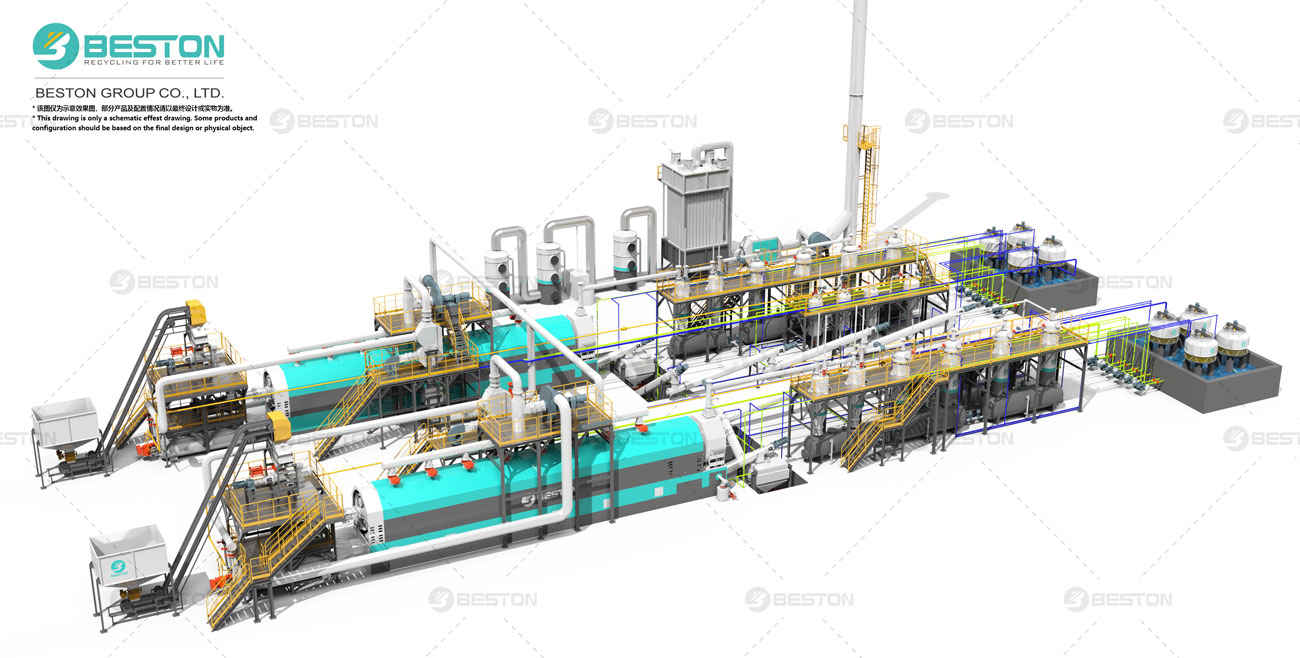

At the heart of thermal desorption unit, also called oil sludge pyrolysis plant for sale lies a sophisticated process that relies on heat to vaporize and separate contaminants from soil, sludge, or other substrates. By subjecting the waste material to elevated temperatures within a controlled environment, volatile organic compounds (VOCs) and hazardous contaminants are driven off, leaving behind clean, remediated material.

Versatility and Adaptability

One of the key strengths of thermal desorption unit is the versatility and adaptability to diverse waste streams and contaminants. Whether dealing with oily sludges, contaminated soils, or hazardous industrial residues, thermal desorption technology can effectively treat a wide range of materials, making it a valuable asset in various industries and remediation projects.

Advantages of Thermal Desorption Units

Efficient Contaminant Removal

Thermal desorption units excel in efficiently removing contaminants from oily hazardous waste, achieving high removal efficiencies even for complex mixtures of pollutants. By utilizing precise temperature control and residence time, these units can effectively target and eliminate a broad spectrum of organic contaminants, ensuring thorough remediation of contaminated materials.

Minimal Environmental Impact

Unlike traditional remediation methods such as incineration or chemical treatment, thermal desorption technology minimizes environmental impact by avoiding the generation of secondary pollutants or hazardous byproducts. The closed-loop system of thermal desorption system ensures that contaminants are safely captured and treated without releasing harmful emissions into the environment.

Resource Recovery

In addition to contaminant removal, thermal desorption units facilitate resource recovery by reclaiming valuable materials from oily hazardous waste. Through the process of desorption and condensation, recovered contaminants can be purified and reused in various industrial processes, reducing the need for virgin materials and promoting resource conservation.

Scalability and Modularity

Thermal desorption units offer scalability and modularity, allowing for customized solutions tailored to the specific needs and requirements of each remediation project. Whether dealing with small-scale spills or large-scale contamination sites, these units can be configured and deployed to meet the demands of any application, ensuring effective and efficient remediation outcomes.

Cost-Effectiveness

Despite the initial investment required for thermal desorption units, their long-term cost-effectiveness is undeniable. By minimizing waste disposal costs, reducing environmental liabilities, and enabling resource recovery, these units offer significant economic benefits over the lifespan of a remediation project, ultimately delivering a favorable return on investment.

Regulatory Compliance

Thermal desorption technology enables compliance with stringent environmental regulations and standards governing the treatment and disposal of hazardous waste. By providing a reliable and effective remediation solution, thermal desorption pyrolysis machine help organizations meet their regulatory obligations and avoid potential fines or penalties associated with non-compliance.

Applications of Thermal Desorption Technology

Soil Remediation

Thermal desorption units are widely utilized in soil remediation projects to treat contaminated soils and sediments, particularly those impacted by petroleum hydrocarbons or industrial chemicals. By effectively removing contaminants and restoring soil quality, these units facilitate the rehabilitation of contaminated sites and support sustainable land use practices.

Oil and Gas Industry

In the oil and gas industry, thermal desorption technology plays a crucial role in managing oily hazardous waste generated during drilling, production, and refining operations. By treating oily sludges, tank bottoms, and drilling cuttings, thermal desorption units help minimize environmental impact and ensure compliance with regulatory requirements in the hydrocarbon sector.

Industrial Waste Management

Thermal desorption units are also utilized in various industrial sectors to manage and remediate oily hazardous waste streams, including chemical manufacturing, metal processing, and transportation. By providing an efficient and environmentally friendly solution for waste treatment, these units help industries reduce their environmental footprint and enhance sustainability. Get more information on oily hazardous waste recycling: https://bestonmachinery.com/

Future Trends and Developments

Technological Advancements

The future of thermal desorption technology lies in continuous innovation and technological advancements aimed at enhancing efficiency, reducing energy consumption, and expanding the applicability of these units to new types of contaminants and waste streams. Research and development efforts focused on improving heat transfer mechanisms, optimizing process parameters, and integrating renewable energy sources will drive the evolution of thermal desorption units in the years to come.

Integration of IoT and Automation

The integration of Internet of Things (IoT) technology and automation into thermal desorption units holds promise for improving operational efficiency, data management, and process control. Real-time monitoring and remote control capabilities enabled by IoT sensors and automation systems will enhance the performance and reliability of thermal desorption units, making them more user-friendly and cost-effective for operators.

Conclusion

In conclusion, thermal desorption units represent a cutting-edge solution for recycling oily hazardous waste, offering unparalleled advantages in contaminant removal, environmental protection, resource recovery, and regulatory compliance. By harnessing the power of heat to remediate contaminated materials, these units play a vital role in sustainable waste management efforts and contribute to a cleaner and healthier environment for future generations.