Rice husk, a byproduct of rice milling, is a promising feedstock for pyrolysis due to its high carbon content and availability. Pyrolysis, a thermochemical process that decomposes organic materials at high temperatures in the absence of oxygen, converts rice husk into valuable products such as biochar, bio-oil, and syngas. However, the efficiency of this process can be influenced by various factors. Understanding these factors is crucial for optimizing the operation of a rice husk carbonizer and improving the yield and quality of the end products.

1. Feedstock Characteristics

The physical and chemical properties of rice husk play a pivotal role in determining the pyrolysis efficiency. These characteristics influence the thermal degradation process, heat transfer, and the rate at which volatile compounds are released.

Particle Size

The size of the rice husk particles directly impacts the heat transfer rate within the pyrolysis reactor. Smaller particles have a larger surface area relative to their volume, which facilitates faster heating and quicker decomposition. Conversely, larger particles require more time to heat up and may result in incomplete pyrolysis. For optimal performance, rice husk should be ground or shredded to achieve a consistent particle size that allows for uniform heat distribution and efficient processing.

Moisture Content

Moisture content is another critical factor in pyrolysis efficiency. High moisture content in rice husk leads to the evaporation of water during the initial stages of pyrolysis, requiring additional energy. This reduces the overall efficiency of the process and can lower the yield of biochar and bio-oil. Typically, moisture content above 15% is considered excessive for pyrolysis. Pre-drying the rice husk before feeding it into the biochar pyrolysis machine can significantly improve the thermal efficiency and reduce energy consumption.

Ash Content

Rice husk contains a relatively high percentage of ash compared to other biomass materials. The presence of ash can have a twofold impact on pyrolysis efficiency. First, it may obstruct the reaction by reducing the available surface area for thermal decomposition. Second, high ash content can affect the quality of the produced biochar, reducing its value for certain applications, such as soil amendment. Monitoring and controlling the ash content in the rice husk feedstock is essential to optimize the pyrolysis process.

2. Operating Temperature

The temperature at which the pyrolysis process occurs has a significant impact on the product distribution and overall efficiency of the system. In general, higher temperatures promote faster thermal decomposition of rice husk, resulting in a higher yield of biochar and bio-oil.

Temperature Ranges

Pyrolysis typically occurs at temperatures ranging from 400°C to 800°C. Within this range, different temperatures favor the production of different products. Lower temperatures (around 400°C to 500°C) favor biochar production, while higher temperatures (500°C to 800°C) are more conducive to bio-oil and syngas production. The temperature must be carefully controlled to strike a balance between maximizing the yield of the desired product and minimizing energy consumption.

Heat Transfer Efficiency

Heat transfer efficiency is critical in ensuring uniform heating of the rice husk within the reactor. Efficient heat transfer helps maintain a consistent temperature throughout the material, preventing areas of under-heating or overheating. The use of advanced reactor designs, such as rotary kilns or fluidized bed reactors, can improve heat transfer and enhance the overall efficiency of the pyrolysis process.

3. Residence Time

Residence time refers to the amount of time the rice husk remains inside the pyrolysis reactor. Longer residence times generally allow for more complete decomposition, resulting in higher biochar yields. However, excessively long residence times can lead to the over-formation of unwanted by-products like tars and gases. Optimizing residence time is crucial for achieving the desired product mix and maximizing overall efficiency.

Impact on Product Yield

Short residence times are typically associated with higher yields of bio-oil and syngas, while longer residence times favor biochar production. The ideal residence time depends on the specific goals of the carbonizer machine and the type of products being targeted. For example, if the primary goal is to produce biochar for soil improvement, a longer residence time may be necessary. However, if bio-oil or syngas is the desired product, a shorter residence time may yield better results.

4. Oxygen Content

Oxygen content in the pyrolysis reactor affects the nature of the pyrolysis process. In traditional pyrolysis, oxygen is excluded to prevent combustion. However, some reactors use controlled amounts of oxygen to accelerate the reaction and improve efficiency, a process known as oxy-pyrolysis. The introduction of a small amount of oxygen can increase the reaction rate and enhance the formation of certain products like syngas, although it may decrease biochar yield.

The pyrolysis plant operator must carefully manage the oxygen levels to achieve the desired product distribution and maintain the process’s energy efficiency. The correct balance between oxygen and heat input is crucial for maximizing the overall efficiency of the rice husk pyrolysis process.

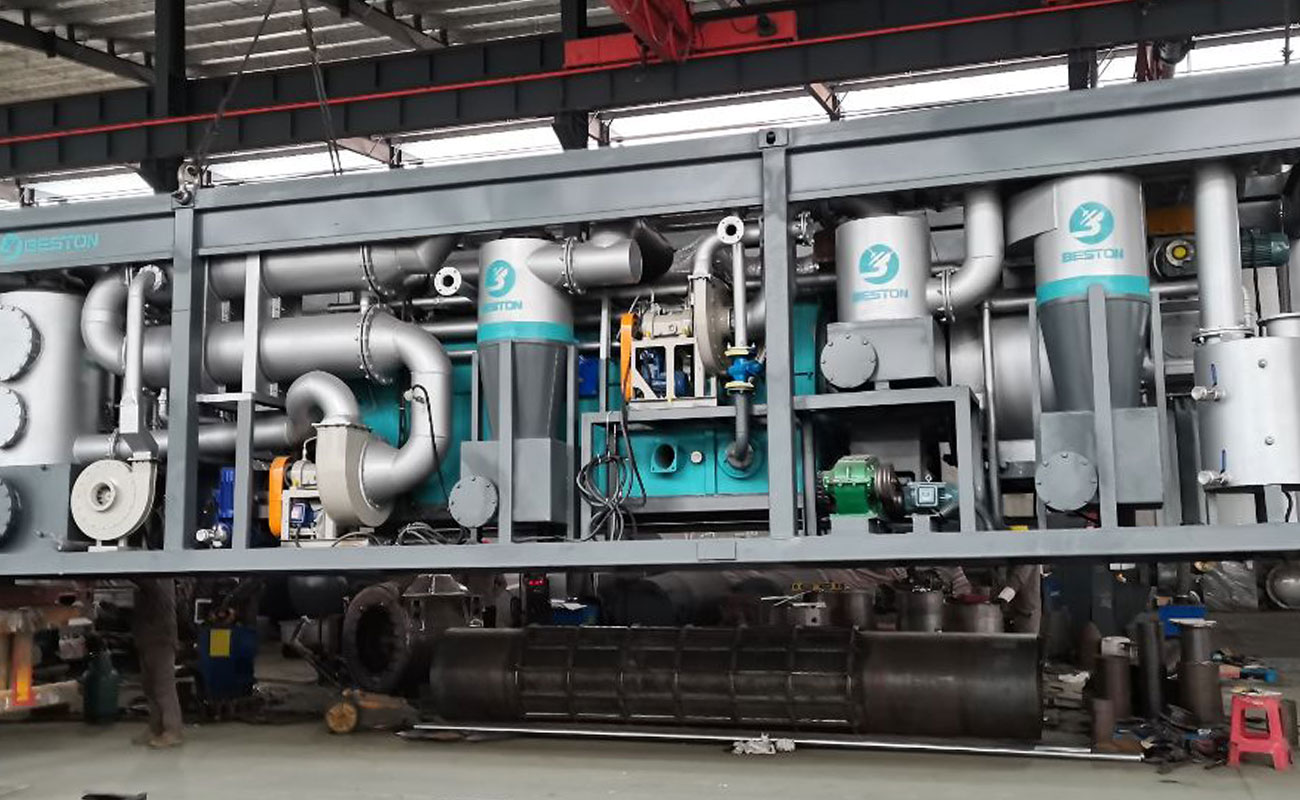

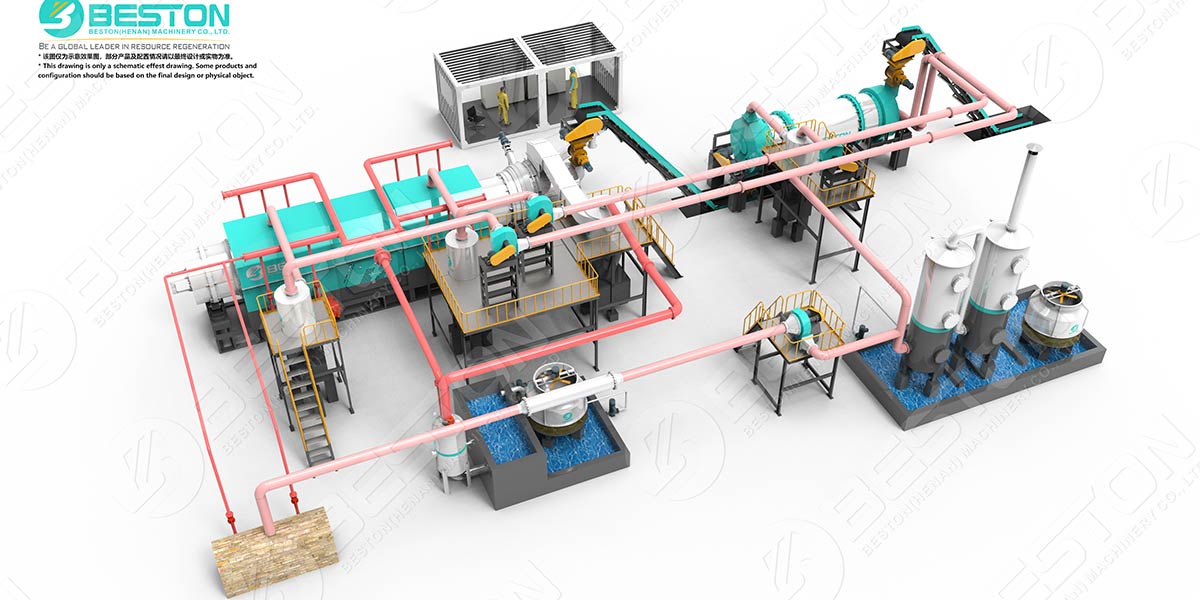

5. Pyrolysis Reactor Design

The design of the pyrolysis reactor itself is another factor that influences the efficiency of the process. Different reactor types, such as fixed bed, fluidized bed, and rotary kiln reactors, have varying heat transfer characteristics and processing efficiencies. A well-designed pyrolysis reactor optimizes heat distribution, minimizes energy losses, and ensures that the rice husk is decomposed uniformly. Looking for a trustworthy reactor manufacturer? Contact Beston Group.

Fluidized bed reactors, for example, provide excellent heat transfer and are ideal for processing rice husk with varying particle sizes. On the other hand, rotary kilns can handle large volumes of feedstock and provide consistent processing, making them suitable for large-scale rice husk pyrolysis plants.