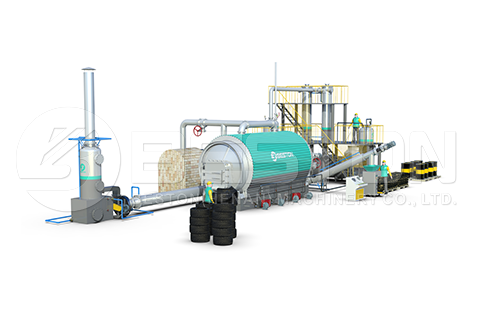

Tyre pyrolysis plant can convert thousands of tons of used tires into usable products every year. One of the biggest selling points of such plants for the tire recycling industry is that they are pollution-free. This means they provide an excellent alternative to conventional methods of scrap tire disposal like incineration and landfill burial. Some of the usable products produced via the tyre pyrolysis plant process are fuel oil, combustible gas, carbon black, and steel wire. In many waste tyre pyrolysis plants, the steel wire is removed before the shredded tires are transferred into the main reactor in order to prolong the service life of the reactor.

The harsh reality of the modern world is that millions of used tires require disposal every year. There are now more cars on the road than ever before, which means countries all the world are having to deal with mounting road tire waste. Many methods of tire disposal are not very environmentally responsible, but the good news is that the popularity of rubber recycling machine is increasing. This means we will hopefully start to see the number of tires send to landfill sites decline. Many countries in Europe have already banned the act of dumping whole or shredded tires at landfills and many leading pyrolysis plant suppliers have lots of customers from European countries, such as Beston Machinery.

Beston is arguably one of the most well-known pyrolysis machine manufacturers and they export their machines to customers in Indonesia, Brazil, UK, South Africa, Philippines, South Korea and more. The company has a special pyrolysis reactor design and a wide selection of pyrolysis plants for sale to match the needs of different customers. The machines with rotary reactors that they manufacturer, for instance, as best-suited for small-scale tire recycling plants that want to operate a batch-based production line. Tire to oil machines with rotary reactors are also more affordable.

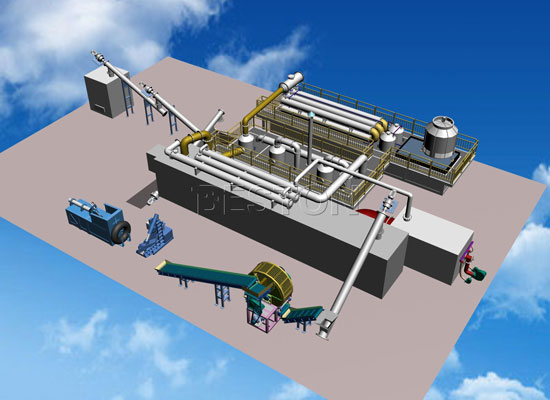

Continuous tire pyrolysis plant cost is much higher, which means such plants are best suited for large-scale tire recycling facilities that can operate round-the-clock and have thousands of tons of waste rubber to process each month. Continuous models have fixed horizontal reactors, which makes them more stable and energy-efficient. However, they also require more floor space.

To avail of the best tire pyrolysis reactor plant prices, businesses need to be prepared to source machinery from overseas suppliers. There are lots of high-quality tire to oil machine suppliers in China and their prices are insanely competitive – even when import taxes, currency conversion fees, and international shipping charges are taken into consideration.

Some of the core specifications those looking to invest in a tire pyrolysis plant for their recycling facility need to bear in mind when comparing different models are daily capacity, floor area, reactor size, heating fuel, reactor pattern, life span, cooling system, total power, working method, and operating pressure. In addition, businesses need to think about investing in other related machinery, such as automatic tire shredders and oil distillation machines. If you want more about the tyre pyrolysis plant cost, please contact Beston Machinery.