When a business invests in, and subsequently sets up a waste pyrolysis plant, it can be difficult to manage. It is because the many components must work together perfectly to ensure the proper production of the byproducts. It is during this process that materials such as plastic, or even organic materials, can be broken down into components that can be sold or used. Setting up the pyrolysis plant to produce these burnable fuels can require some ingenuity. Here is how most pyrolysis plants are set up if you want to get optimal production out of all of them.

How Most Are Set Up Today

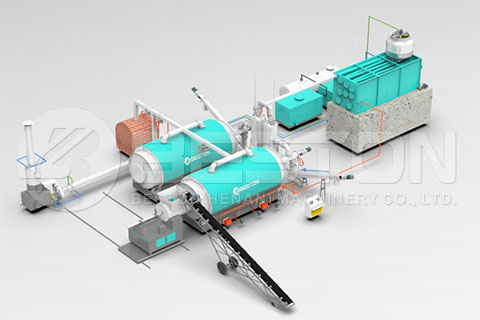

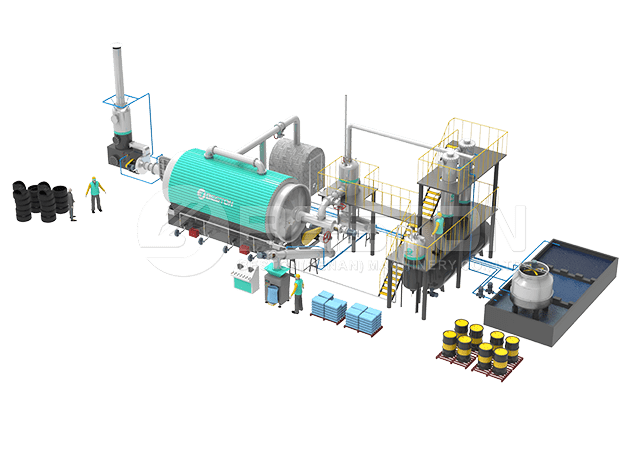

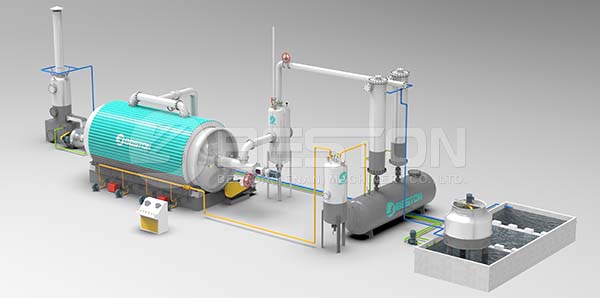

Most of these are quite elaborate today unless you have it simple pyrolysis machine. The plants are designed to handle tons of material and produce byproducts such as charcoal, oil, kerosene, and even diesel fuel after the distillation process has occurred. It begins with an area where the initial materials are broken down in size. They are also cleaned significantly and then dried out. These will be placed into the pyrolysis reactor, sometimes first going through some form of the extruder. It is during this process that it will be heated, and the different components separated, some of which will go through a distillation procedure. The solid materials will be stored as charcoal. Once the distillation process is over, the liquid material that remains will be separated into containers depending upon the fuel that was made. Below is a Beston pyrolysis plant in the UK.

Are These All Set Up In The Same Order?

In most cases, the order is going to be identical. That is because the process must occur in a certain way to get the same results. The only difference is that it may have a CHP unit at the end of the process, or perhaps they may not have an extruder that is very elaborate. Otherwise, everything will be placed into the machine in the same exact way and processed to create the oil and charcoal. If you have an elaborate machine, the components may look very different, but they still work in the same exact way. If you were to look at a smaller pyrolysis machine, the internal mechanisms are also the same. You are simply taking material such as waste material from harvesting, sawdust, plastic, rubber, and changing this into components that can still have a combustible value that is marketable. More cost information: https://wasterecyclingplant.com/plastic-pyrolysis-plant-cost.

Setting up a pyrolysis plant could take several days depending upon its size and capabilities. You may need to bring in extra help that will have cranes or forklifts that can assist. It’s also good to have a person on board that has done this before. Not only can they set everything up properly, but they can also make adjustments on the furnace, scrubbers, distillation sections, as well as the conveyor belts that are sometimes used. Once it is set up, and if it is working properly, this will provide you with a very nominal way of removing waste products from your facility and converting them into something useful. More videos can be found: https://www.youtube.com/channel/UC9zzn9329OyvomwOlrxNjSQ.