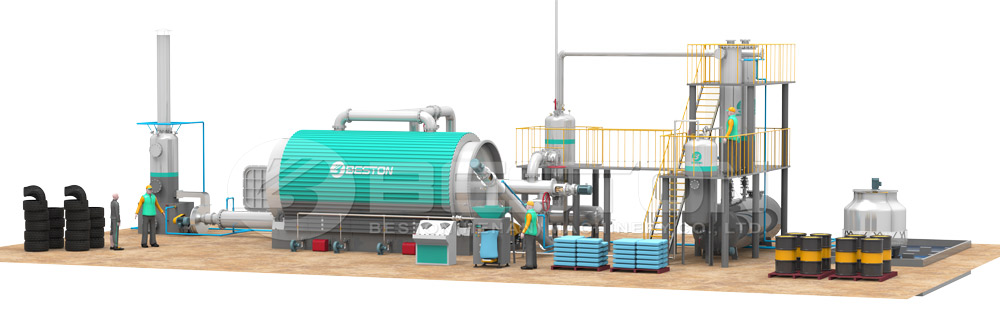

If you’re planning to invest in the environment, the tyre to fuel plant is an exceptional way to do so. This is achieved using the pyrolysis process which is different from burning tyres to accomplish the same product. Besides fuel, by-products such as steel wire, combustible gas, and carbon black are all produced via the process.

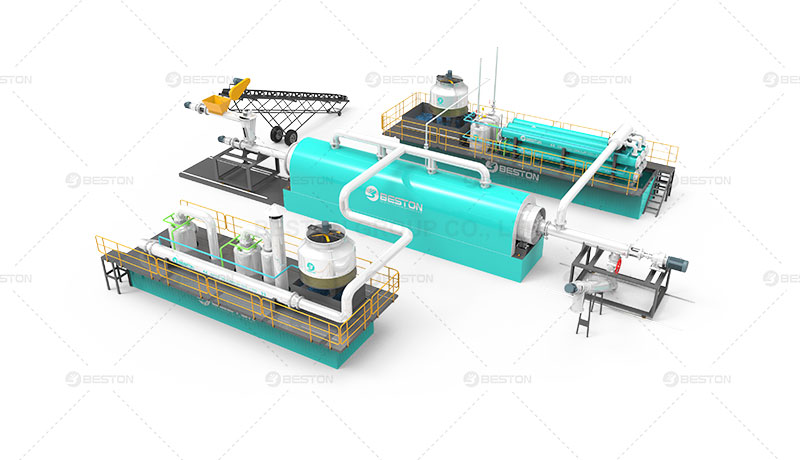

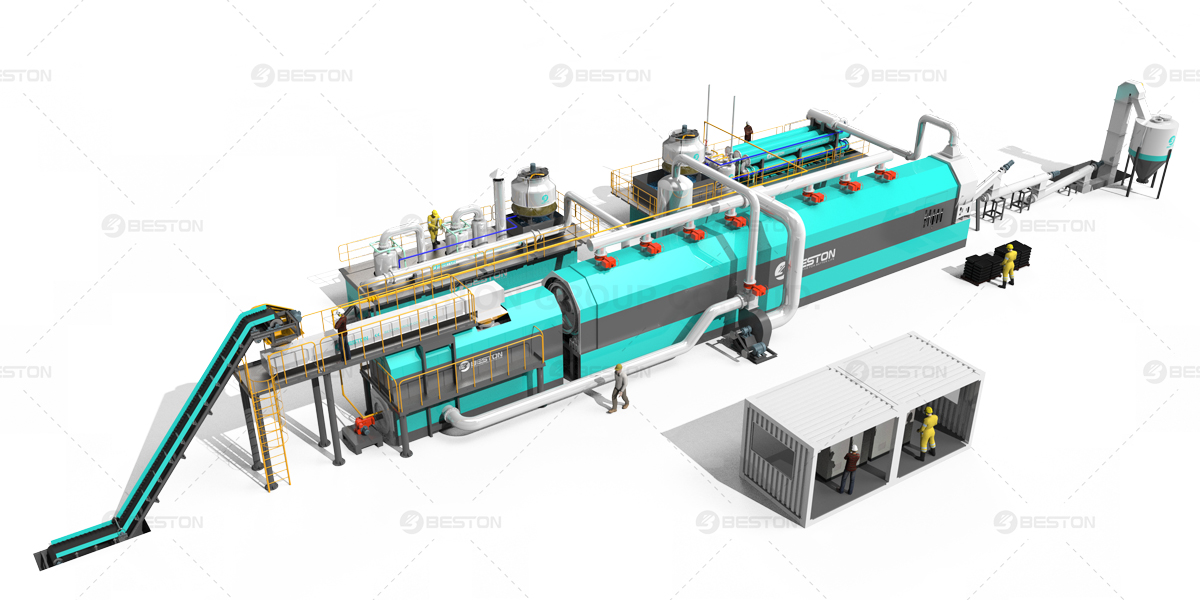

If you didn’t already know, these plants are superior for several reasons. The main one is the originality of the design. The heating structure combines wind and fire heating to increase the efficiency of the machine. Additionally, the protective casing on the tyre to fuel recycling plant‘s reactor ensures that it stays protected from very high temperatures.

Since the plant is fully automatic, it has the ability to produce up to a whopping 24 tons each day. The combustible gas produced is then collected and used as a heating source for the plant. This simply reduces the cost of fuel. As previously mentioned, the all-new protective casing also prevents heat loss.

The plant easily offers its owners a higher safety standard. Most of Beston tyre pyrolysis plant are known for having some of the best fire-proof, explosion-proof, and burn-proof capabilities. The added pressure and thermometer gauges also increase the safety functions.

Additionally, the tyre recycling plant is also even more eco-friendly since the filtering system is produced to meet the highest environmental emission standards. Water is also saved and never wasted because of the circulation in the hydro seal. As previously stated, tyre oil is produced. However, this is commonly referred to as pyrolysis oil.

Oil is a main product of the recycling process and it has a ton of other uses. In some instances, users tend to refine it. When this is done, you’ll be left with diesel oil that is seen as even more valuable and eco-friendly.

Other by-products such as carbon black and steel wires can also be sold for a nice profit. Carbon black on the other hand is typically used as a raw material in the production of fortified, as a colorant in rubber, filler, and even in the plastic industry. When it is ground, you can even get a finer version of carbon black which fetches for a higher price.

Unlike many other recycling processes, using the pyrolysis plant in this way is much better than some of the typical traditional methods and the raw material is very easy to source: https://www.bestongroup.com/pyrolysis-plant-for-sale/. If for some reason you’re unsure, you can easily purchase waste tyres from companies that do transportation of some sort. By recycling the old tyres, you’ll not only be doing some good for your country but you will also be doing the environment a huge favor.