If you are interested in setting up a waste tire recycling plant, you may be wondering how much it costs to run a fully automatic pyrolysis plant. In this article, you’ll learn about the operating costs of such a plant, the process of turning waste tires into fuel oil, and the steps involved in pre-treatment before pyrolysis. We’ll also discuss the benefits of converting waste tires into fuel oil.

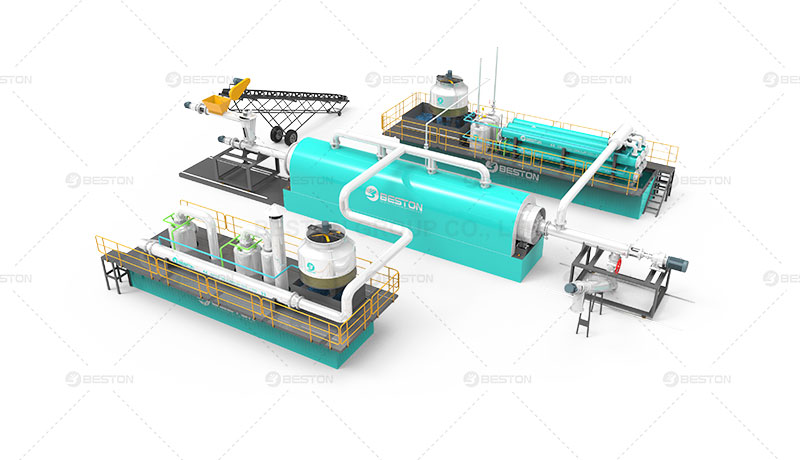

Continuous pyrolysis plant

Using a continuous pyrolysis plant(planta de pirolisis) is an environmentally friendly way to recycle waste materials and produce valuable products, such as oil and gas. This process requires a continuous supply of source material to the pyrolysis reactor, and is performed under high temperatures. The solid wastes are fed into the reactor using a screw conveyor from a hopper. The plant’s heating system uses a fuel burner, and the source material is decomposed when the temperature reaches a preset value. The resulting oil and gas go through a special condenser, and the cooled gas is recycled as a heating fuel.

A continuous pyrolysis plant is more efficient than a batch pyrolysis plant. This type of plant can process 24 tons of raw material per day, and is highly productive for processing a large volume. Its modular design makes it easy to transport and install. If you plan to process a large volume of raw materials, then purchasing a continuous pyrolysis plant is a good investment. The Beston Company even makes a mobile version.

Operating costs of a fully automatic pyrolysis plant

A fully automatic pyrolysis plant(planta pirolisis neumaticos) is capable of recycling various wastes into fuel and oil. The plant is easy to install and operates without manual labor costs. It meets all the emission standards of Europe. The end product oil can be recycled in a number of ways. Depending on the process, it may generate some gas. In a fully automatic pyrolysis plant, a portion of the gaseous component is recycled into another fuel or used for other purposes.

Pyrolysis plants can be a big investment. In order to operate efficiently, the machine requires high-quality fuels. The investment may also include the hiring of people to maintain the equipment. However, it can save considerable amounts of money in terms of the end products. The process of pyrolysis can generate a substantial amount of income, even after the initial investment. This investment can be quite profitable if the end products produced by the plant are of high quality.

Process of converting waste tires to fuel oil

A tire pyrolysis plant(https://www.bestoneco.com/planta-de-pirolisis-de-lodo-aceitoso/) is an environmentally friendly way to recycle large amounts of waste tires. This process burns the waste tires at high temperatures in the absence of oxygen, which causes them to break down into smaller molecules of pyrolysis oil and gas. They also generate useful products, such as carbon black and steel wire. In addition to fuel oil, the process can also produce electrical energy.

The process of converting waste tires to fuel oil in a pyrolysis plant begins by feeding waste tires into a reactor. The waste tires are heated using an automatic feeder and a heating system. Once the tyres reach temperatures of between 280 and 320 degrees, they start to crack. The oil and gas then pass through a buffer tank to slow down the reaction and ensure a more uniform condensation effect. The buffer tank can also help to precipitate the oil residue before it reaches the final product.

Pre-treatment of waste tires before pyrolysis

There are two types of pyrolysis plants: batch and continuous. Batch plants do not require pre-treatment, while continuous plants do. The batch plants do not require pre-treatment, but they do require a shredder machine. The pyrolysis process can produce fuel and produces almost no waste or emissions. The resulting oil is used in the production of fuel or chemicals.

The oil from waste tyre pyrolysis is composed of Asiatic and aromatic compounds with varying amounts of hetero-atoms. This product is low in octane number and is not considered high-grade oil. The yield of the various products depends on the temperature and heating rate of the process, feed particle size, and catalysis. The amount of gas produced depends on the type of catalyst and the reactor configuration.

Quality of fuel oil produced by pyrolysis plant

A fast pyrolysis plant (beston pyrolysis)has been the solution for many industrial applications. The process is a cost-effective, fast way to produce fuel oil. It is also a sustainable and environmentally friendly process. During its development, the technology helped many companies and governments save a considerable amount of energy and money.

A successful pyrolysis plant requires extensive experimental work in several scales. The design of a process requires a critical mass of people and experience in chemical analysis and modeling. The cost of an automatic pyrolysis plant pilot can range from a few million EUR to several millions of euros by 2020. The cost of an industrial scale pilot plant is much more expensive than a bench-scale operation.