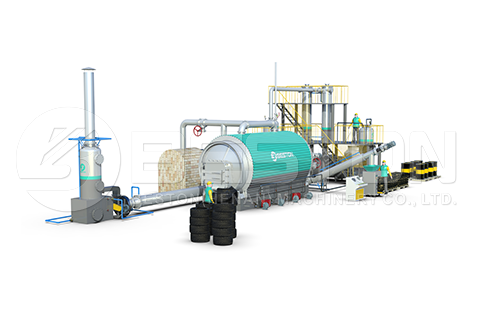

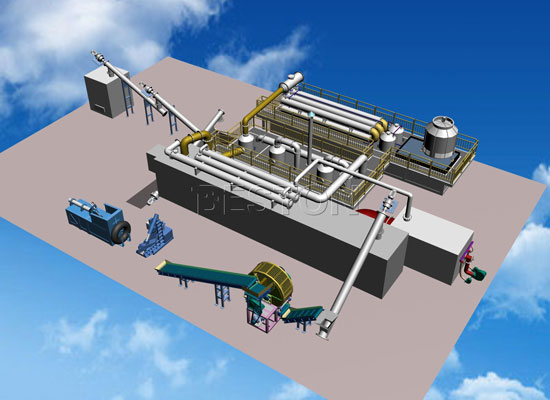

Investing in a tyre pyrolysis plant can be a smart choice for a number of reasons. You can convert old tires into oil and other substances that are highly valuable, like oil. You may receive tax breaks for working with recycled materials. Of course, the best thing is to lower your tyre recycling plant cost.

Decide What You Are Comfortable Spending

Before you buy something like this, you’re going to have to decide what you are willing to spend. Most pyrolysis plants are expensive, but there are options on the lower end that work very well, for example, you can look for the pyrolysis machine for sale from China. In addition, there are a number of ways that you can save on a purchase like this.

Once you know what you are comfortable spending, you can work on learning more about the options that are within your price range. Having a budget in mind will allow you to rule out certain options and focus on machinery that you can afford.

Look At All Of Your Costs

There are a lot of costs associated with the waste tyre pyrolysis plant. You’ll have to purchase more than the machinery. You’ll also have to cover a number of other expenses. For example, you’re going to have to cover the cost of utilities. If you’re fully aware of all of these costs, you’ll be able to make sure you can afford to keep your plant up and running. You can’t ignore major expenses when you are making an investment like this. If you don’t look at your costs over time, you may wind up with bills that are difficult to pay for. However, if you are aware of all of your costs, you’ll be able to plan accordingly and make sure you use your money wisely.

Compare Your Options

You shouldn’t just look at a handful of options when you’re shopping for a plant. Instead, you should try to look at some of the different tyre pyrolysis machines for sale. If you compare these plants against each other, you’ll be able to discover the options that offer the best value for the price. Look at all of your options with care and decide what sort of plant you would most like to invest in. No matter what you ultimately decide to purchase, you should feel comfortable with the decision that you’ve made. Here is a website for your reference: https://wasterecyclingplant.com/waste-tyre-pyrolysis-plant-for-sale/.

Find Ways To Lower Your Expenses

This can be a major purchase, but thankfully, there are a lot of ways for you to bring your costs down. You should be able to lower your expenses considerably, which will make it easier for you to find a plant that is actually affordable for you. Whether you buy from a vendor with lower rates or invest in an energy-efficient pyrolysis plant, there are numerous ways that you can save. Focus on finding ways to save so that you can get what you want for less.

You should keep all of these things in mind if you’re focused on finding the right tyre pyrolysis plant for sale. Make sure you’re able to purchase a plant that will work for you. More details about the waste recycling business can be found: https://wasterecyclingplant.com/.