Given that consumers and industry are both in search of natural and sustainable ways to produce energy it would seem that the biochar production business is set to grow during 2023 and beyond. Go on reading: https://www.bestongroup.com/.

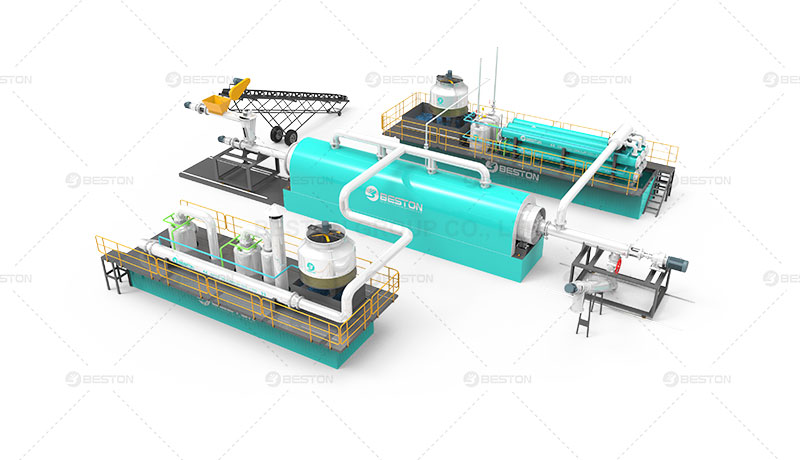

What is Biochar? Biochar is a carbon-rich material that is made through the application of heat in an oxygen-free environment. This process is known as pyrolysis. Biochar is typically made from organic vegetable waste (biomass). This can be gathered from farms or land that has been cleared for development. The sustainability and ‘Green Credentials’ of the Biochar manufacturing process are in part due to the fact that very little gas or smoke is released during the manufacturing process by biochar making machine.

Biochar has a variety of uses. The material is composed mainly of carbon and is highly porous, with a large surface area, making it ideal for a variety of industrial and commercial uses. It is particularly valuable for the purpose of enriching soil and as the main ingredient in fertilizer. It helps to promote water retention, improves porosity, decreases acidity, and regulates nitrogen leaching. It can also help to speed up the composting process, as well as enrich the end result.

The process of making Biochar is, in essence, a simple one. It requires an airtight container to act as the kiln or stove and the ability to heat that container. It also requires a scalable and reliable source of organic matter that does not contain contaminants. Waste that is gathered from industrial sites for instance will usually not be suitable for the manufacture of biochar due to the contaminants it contains such as heavy metals. This type of soil can contain traces of cadmium, copper, chromium, lead, zinc, and mercury, among many others.

The simplicity of the Biochar manufacturing process and the low entry levels required for entrepreneurs to start up a Biochar business is one of the strengths of the process. Given that 1 ton of Biochar stores carbon that would have otherwise generated 3.6 tons of carbon dioxide it is one of those technologies that holds enormous promise in allowing developing nations to decrease their carbon footprints, while at the same time offering employment opportunities to the populace.

The scalable nature of biochar machinery also means that it is perfect for large-scale rollout. This carbonization equipment is incredibly robust and is manufactured and supported by international manufacturers with a reputation for producing machinery that is able to cope with the harshest of industrial environments. The machinery also requires limited maintenance making it even more attractive in terms of the return on investment.

Biochar equipment is available to process a number of raw ingredients such as municipal waste, rice, and coconut husks, and sugarcane byproducts. Investment in this type of equipment is one of the rare instances where the environment benefits from industrial production, communities benefit through job creation, and the market benefits through the production of a valuable resource that can enrich the soil and help grow crops in countries that might be suffering from problems including malnutrition.