Although some advances have been made in the sustainable treatment of waste there is still an enormous backlog of certain waste that regularly makes its way to landfills across the country.

There are a number of materials and products that should be singled out due to the sheer volume of waste that they generate, and the potential that they have to pollute groundwater and ecosystems as they biodegrade. Among the worst culprits are used tires and various types of plastics. The average car tire (for example) takes between 50 and 80 years to biodegrade. During the course of this time that tire will continuously be releasing potentially damaging toxins and compounds into the environment.

The Pyrolysis Solution

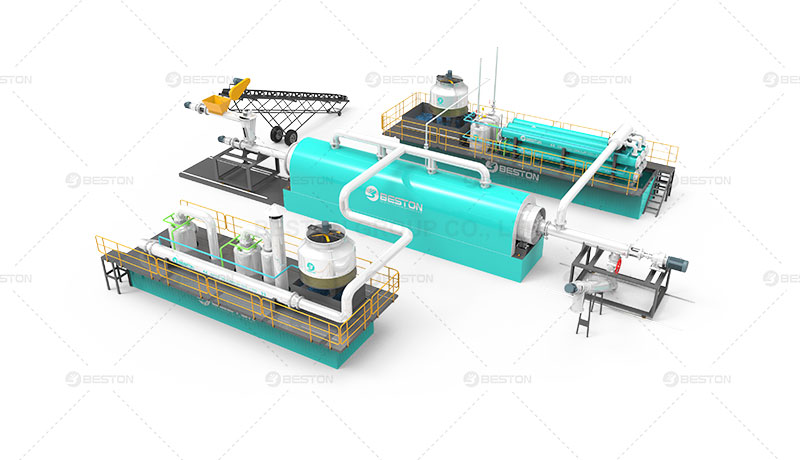

Fortunately an increasingly popular way of dealing with tires and other plastic waste is by using pyrolysis (máquina de pirólisis) to break down the tires into their component molecules. Pyrolysis is a thermochemical process, which means it relies on heat and chemical reactions to break down the raw material that is fed into pyrolysis plants. The process of pyrolysis will take place in a furnace that has been heated to between 400–800°C. This process takes place in an oxygen-free or extremely low-oxygen environment.

One of the advantages of this type of process and the absence of oxygen is that the pyrolysis plant releases very few air pollutants, making the process environmentally friendly.

The result of this type of pyrolysis (that can be used on a variety of organic, carbon-based raw material) is the production (through chemical and physical separation) of a variety of compounds and products that are produced as the gas cools. These products will range from biofuels to the by-product of carbon black, which will be sold back to tire manufacturers. In the case of tires, there will also be the metal bands that provide structure to the tires. This material will be separated from the biofuel and other material formed as a result of the pyrolysis process (planta de pirólisis de neumáticos), and also sold to a variety of industries for reuse.

Types of Plants

There are two main types of pyrolysis plants that are today in general use. The first is the Continuous Pyrolysis plant. This is generally used where raw material is available on-site in sufficient quantities to ensure that the plant can operate 24 hours a day. The second type of plant is the Batch pyrolysis plant (https://www.bestoneco.com/instalacion-planta-de-pirolisis-en-dominica/). This plant processes raw material in batches (as its name would suggest). It is much more forgiving when it comes to the preparation (such as pre-washing) of the raw material. The Batch plants can also process a wider array of raw materials than the Continuous pyrolysis plant.

For investors that are in search of robust plant and machinery that is both extremely durable and low maintenance, the Batch pyrolysis plant may offer exceptional return on investment. Ther is raw material in abundance – and a ready market (BESTON GROUP CO., LTD.) for the products that are produced during the pyrolysis process. Both of these factors contribute to a firm fundation for a profitable and sustainable business.