A continuous pyrolysis plant is a type of waste management facility that is able to convert organic waste materials into combustible gas and other useful products. This process, known as pyrolysis, occurs when the organic matter is heated in the absence of oxygen. The resulting products can include things like charcoal, bio-oil, and synthesis gas, which can be used as fuel for power generation or other industrial processes. The continuous pyrolysis plant is typically large-scale facility that are designed to handle high volumes of waste. As such, they are often used by municipalities or other organizations that generate large amounts of organic waste.

Working Mechanism

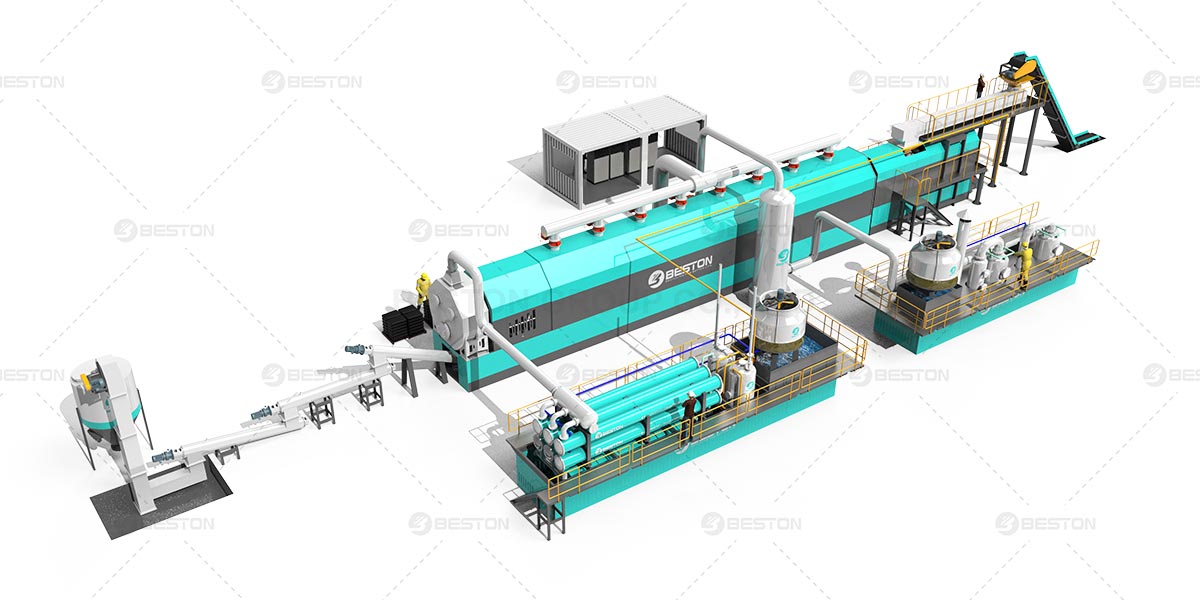

This type of plant essentially consists of four main parts: a feeder, reactor, condenser, and gasifier. The feeder is used to introduce the material to be pyrolyzed into the reactor. The reactor is where the actual process of pyrolysis takes place. It is heated to a very high temperature (usually between 700-900 degrees Celsius) in order to break down the hydrocarbon chains. The vapor and gas produced in the reactor are then passed through the condenser, where they are cooled and condensed back into liquid form. Finally, the gasifier is used to remove any solid impurities that may remain after condensation.

The entire process takes place under a vacuum in order to prevent oxygen from coming into contact with the hydrocarbons and causing them to burn. When operated correctly, a continuous pyrolysis machine for sale can achieve a very high degree of hydrocarbon conversion. This makes it an attractive option for waste disposal and recycling, as well as for producing fuel and other valuable chemicals from organic materials.

Advantages Of Using a Continuous Pyrolysis Plant

A continuous pyrolysis plant offers a number of advantages over other waste disposal methods, such as incineration and landfill. Pyrolysis is a thermal decomposition process that breaks down organic matter into combustible gases and char. The gases can be used to generate electricity, while the char can be used as a soil amendment. Furthermore, the continuous pyrolysis process is highly efficient, with little to no waste material left over. In contrast, incineration leaves behind hazardous ash that must be disposed of in a landfill, while landfill results in the generation of methane gas, which is a major contributor to climate change. Continuous pyrolysis is therefore a much more environmentally-friendly option for waste disposal. Check the skid-mounted pyrolysis plant here.

How To Choose the Right Continuous Pyrolysis Plant

If you are in the market for a continuous pyrolysis plant, there are a few things you should keep in mind to ensure you choose the right one for your needs. First, consider the capacity of the plant. You will want to choose a plant that can handle the amount of waste you generate on a daily basis. Second, consider the type of waste you will be processing. Some plants are designed for specific types of waste, such as plastics or tires. Make sure the plant you choose can handle the type of waste you will be feeding it. Finally, consider the cost of the plant. You will want to choose a plant that is affordable and will fit within your budget.

The continuous pyrolysis plant is an efficient way to break down these materials and turn them into valuable products. If you are interested in starting your own pyrolysis plant, make sure you compare different plants before investing in one. Find more information on Beston Group here.