In the dynamic landscape of environmental conservation and sustainable practices, the United States is at the forefront of exploring innovative solutions to mitigate climate change and reduce carbon emissions. Among these solutions, charcoal making machines have emerged as a potential game-changer, offering not only a practical approach to waste management but also a pathway to earning carbon credits. This comprehensive guide delves into the intricate world of charcoal making machine in the United States and their role in generating carbon credits, uncovering the synergy between sustainable practices and economic benefits.

Chapter 1: The Carbon Conundrum

The global imperative to address carbon emissions and their impact on climate change is a pressing concern. This chapter delves into the carbon challenge facing the United States and highlights the importance of finding effective solutions that align with international climate goals.

Chapter 2: Charcoal Making Machines: A Green Revolution

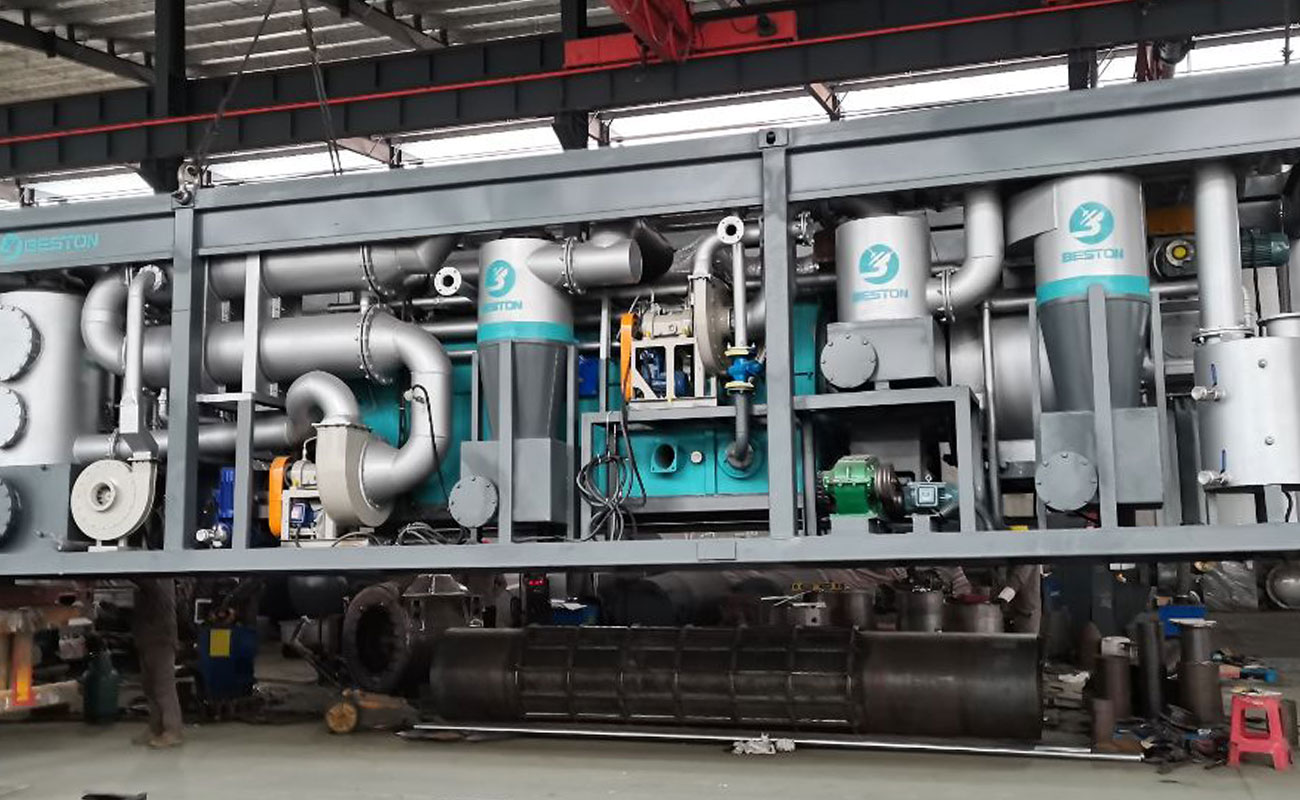

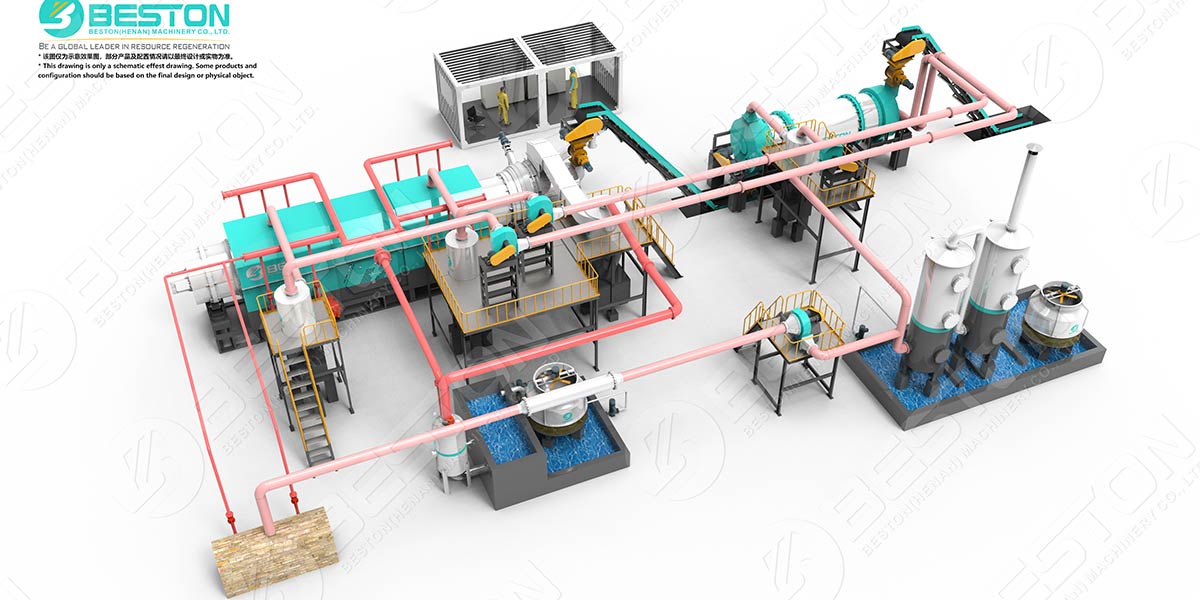

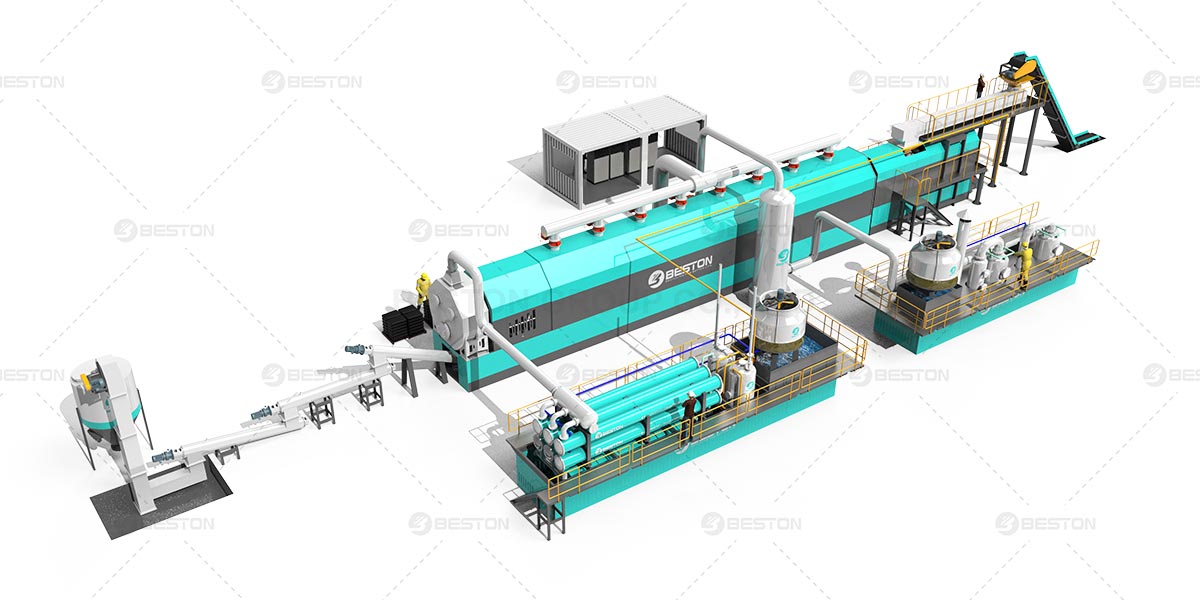

At the heart of the carbon credits journey lies the ingenious technology of charcoal making machines. This chapter provides an in-depth exploration of the functionality and processes of these machines, emphasizing their ability to transform organic waste materials into valuable charcoal.

Chapter 3: Carbon Credits Demystified

Carbon credits, a mechanism introduced under international agreements like the Kyoto Protocol and the Paris Agreement, provide a financial incentive for businesses and industries to reduce their carbon emissions. This chapter offers a comprehensive overview of carbon credits, their trading mechanisms, and their role in promoting sustainable practices.

Chapter 4: The Carbon Sequestration Potential of Charcoal

Charcoal, produced through the carbonization process facilitated by portable biochar kiln, plays a pivotal role in carbon sequestration. This chapter delves into the science behind carbon sequestration, explaining how charcoal can serve as a carbon sink and contribute to offsetting carbon emissions.

Chapter 5: Charcoal Making Machines and Carbon Credits

The nexus between charcoal making machines and carbon credits is a promising prospect. This chapter uncovers how the carbon sequestration potential of charcoal production aligns with the criteria for earning carbon credits. Real-world case studies illustrate successful integration of charcoal making machines into carbon credit initiatives.

Chapter 6: Environmental and Economic Synergy

The utilization of charcoal making machines not only aids in carbon emissions reduction but also fosters economic opportunities. This chapter explores the dual benefits of these machines, including waste management, carbon emissions reduction, and potential revenue streams through carbon credit trading.

Chapter 7: The Legal and Regulatory Landscape

Navigating the realm of carbon credits involves understanding legal frameworks and regulatory mechanisms. This chapter delves into the requirements, processes, and certifications necessary for generating and trading carbon credits in the United States. Take more information of price on this web: https://bestonmachinery.com/coconut-shell-charcoal-making-machine-price/.

Chapter 8: Charcoal-Made Carbon Credits in Practice

From sustainable forestry management to agricultural residue utilization, charcoal making machines find application across diverse sectors. This chapter delves into the practical aspects of integrating charcoal production into carbon credit projects and showcases success stories.

Chapter 9: The Future of Carbon Credit-Earning Charcoal

As the world gravitates towards a low-carbon future, the potential of charcoal making machines to earn carbon credits gains prominence. This chapter speculates on the future trends, innovations, and opportunities in this field, emphasizing the role of technology and market dynamics.

Conclusion: Pioneering Sustainable Transformation

In conclusion, the convergence of charcoal making machines and carbon credits exemplifies the potential for harmonizing environmental conservation with economic growth. By effectively sequestering carbon and generating carbon credits, these machines empower businesses, industries, and communities to contribute meaningfully to carbon emissions reduction targets. The journey towards a more sustainable United States is illuminated by the transformative potential of charcoal making machines, where waste turns into valuable resources and environmental stewardship becomes a catalyst for positive change.