There are plenty of opportunities in the modern world. If you have an entrepreneurial mindset, you have enormous number of options but modern entrepreneurs prefer to invest in businesses that are environmentally friendly and still have the potential to grow a lot. One of the businesses that is environmentally friendly and offers an excellent potential for growth is recycling of waste materials such as waste tires through pyrolysis technology. Pyrolysis process causes breakdown of long molecular chains into shorter molecular chains. This process converts a variety of waste materials into other useful products. Here’s a list of some of the major advantages of investing in a pyrolysis machine.

Environmentally Friendly

One of the biggest advantages of investing in pyrolysis technology is that it is an environmentally friendly business. Waste tires cause a lot of pollution when these are thrown into the landfills. The harmful chemicals from these waste tires keep leaching into the groundwater and pollute everything. By processing waste tires into useful materials, you can play your part in getting rid of this huge environmental problem.

Consider the fact that over a billion waste tires are thrown into landfills each year and this number is always increasing as people keep buying new cars or other vehicles and keep changing their tires. Investment in pyrolysis technology allows you to build a business with high growth potential while playing your part in making the planet green. Click here to know more: https://bestonpyrolysisplant.com/waste-tyre-pyrolysis-plant-suppliers/.

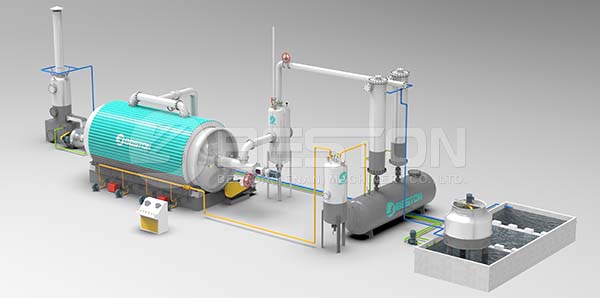

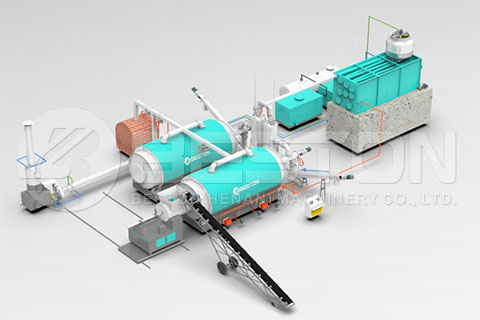

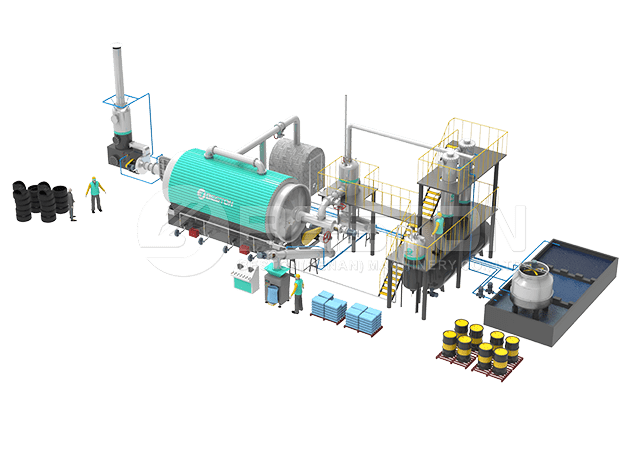

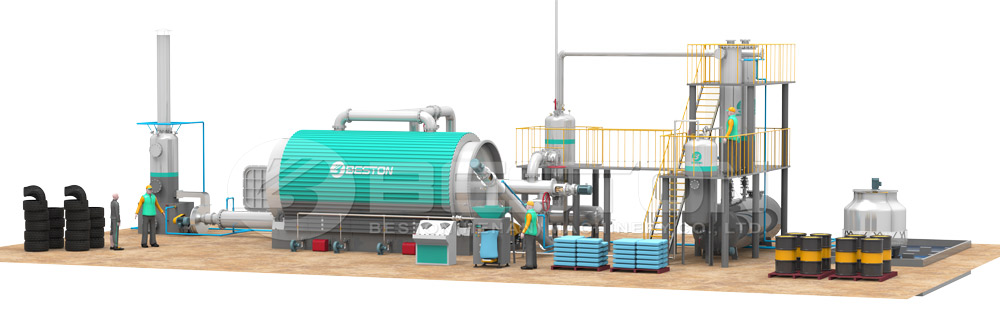

If you do your homework and take due care in setting up the pyrolysis machine, it is an almost hassle-free business that runs like clockwork. You get the raw material in and process it and let the machine do its job in order to get products that are in high demand in various industries. You will, of course, need to tie up with suppliers as well as buyers and do all the other things that a business is required to do but on the technical side of things, you don’t need to worry much provided you invest in a high quality Beston waste tyre pyrolysis plant that runs without any problems.

Products in High Demand

All the final products obtained through the pyrolysis process are in high demand in a variety of industries. Major products obtained through this process include fuel oil and carbon black. Fuel oil can be used as such or it can be distilled to obtain diesel oil. Similarly, carbon black obtained through this process is also in high demand in a variety of industries. In short, you would never have problems with finding buyers for the final products obtained through this process.

Overall, these are some of the major advantages of investing in a pyrolysis machine. It is also important for you to know that not all the pyrolysis plants are the same. The modern plants have better design and much better efficiency as compared to the old machines. This is why, you need to pay special attention to the features of the machine when buying a pyrolysis plant in order to get the most value out of your investment.