Plastic pyrolysis is a process that holds significant promise in addressing the environmental challenges posed by plastic waste. As the world grapples with the escalating issue of plastic pollution, innovative technologies like plastic pyrolysis equipment emerge as potential solutions. In this comprehensive 3089-word post, we will delve into the plastic pyrolysis process, exploring its principles, benefits, challenges, and potential impact on the global plastic waste crisis.

Introduction to Plastic Pollution:

Plastic pollution has become a pervasive environmental concern, with millions of tons of plastic waste generated each year. The conventional methods of plastic disposal, such as landfilling and incineration, contribute to environmental degradation and resource depletion. In this context, alternative approaches like plastic pyrolysis offer a ray of hope in transforming the way we manage plastic waste.

Understanding Plastic Pyrolysis:

Plastic pyrolysis is a thermal degradation process that involves breaking down plastic polymers into smaller hydrocarbons in the absence of oxygen. This is a departure from traditional methods that often result in the release of harmful emissions. The pyrolysis process typically occurs in a controlled environment, with the absence of oxygen preventing the combustion of plastic, thereby minimizing the release of toxic gases.

Key Steps in the Plastic Pyrolysis Process:

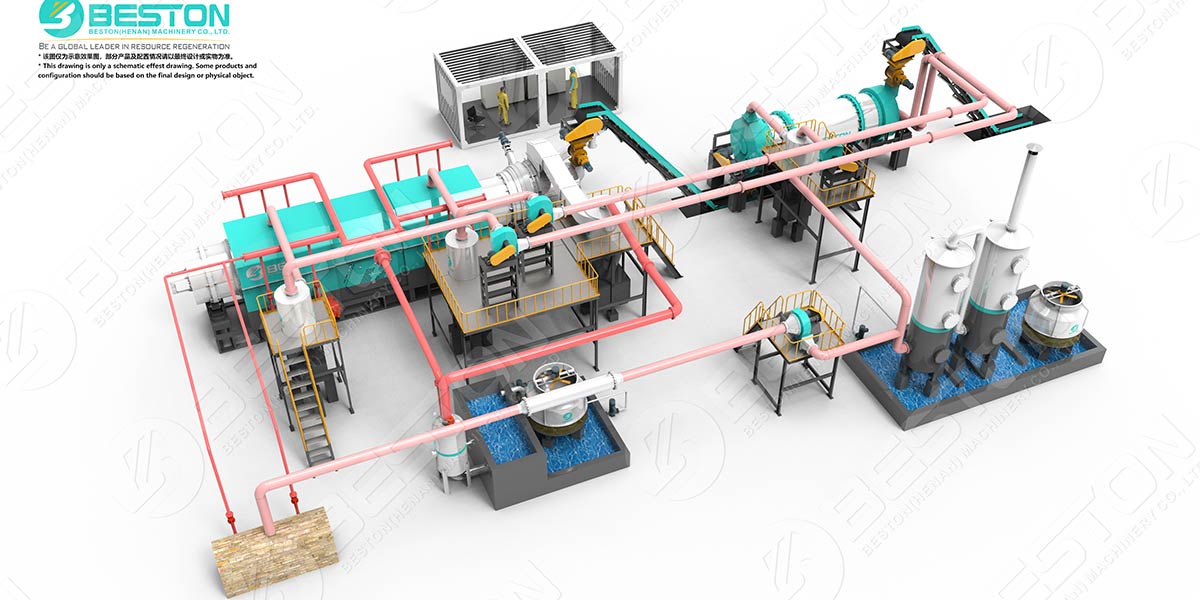

Feedstock Preparation:

The process begins with the collection and sorting of plastic waste. Various types of plastics, including polyethylene, polypropylene, and polystyrene, can be used as feedstock for pyrolysis. The collected plastic is then sorted and prepared for the next stages of the process.

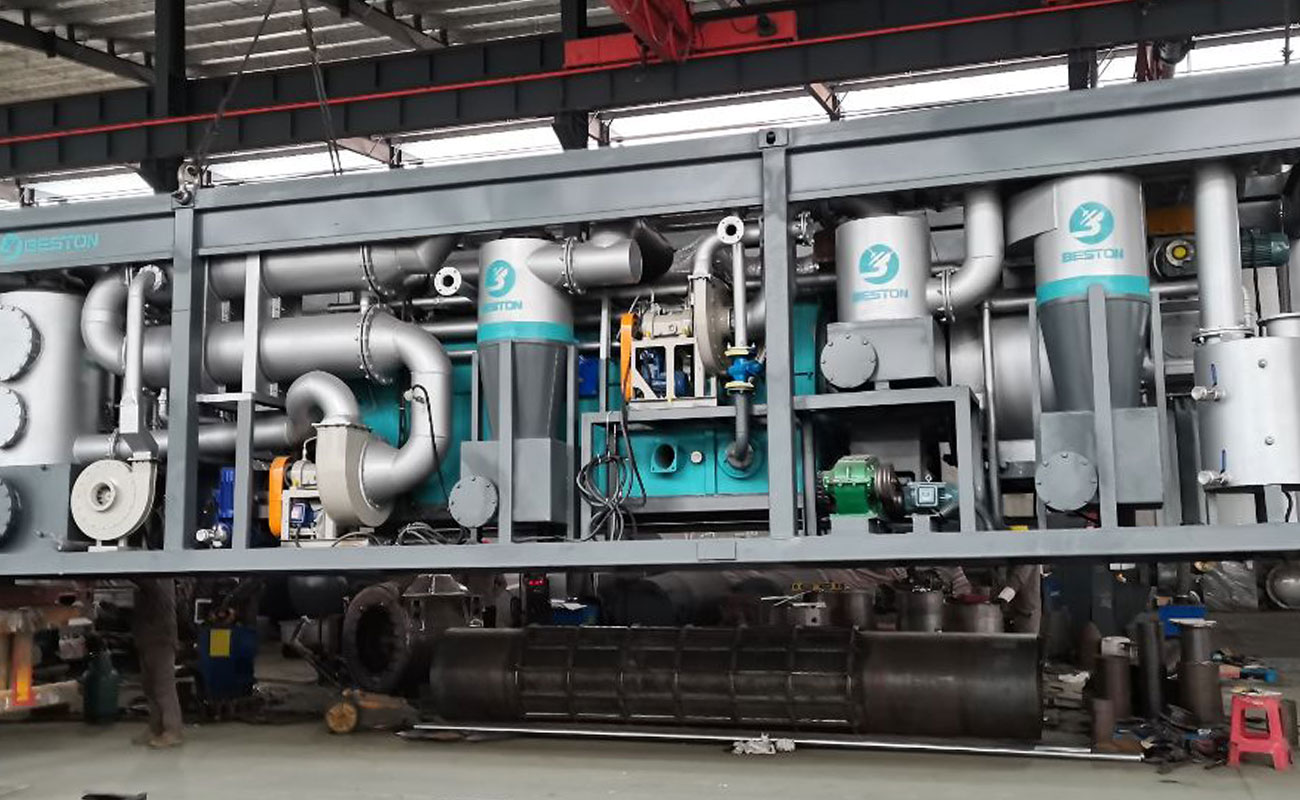

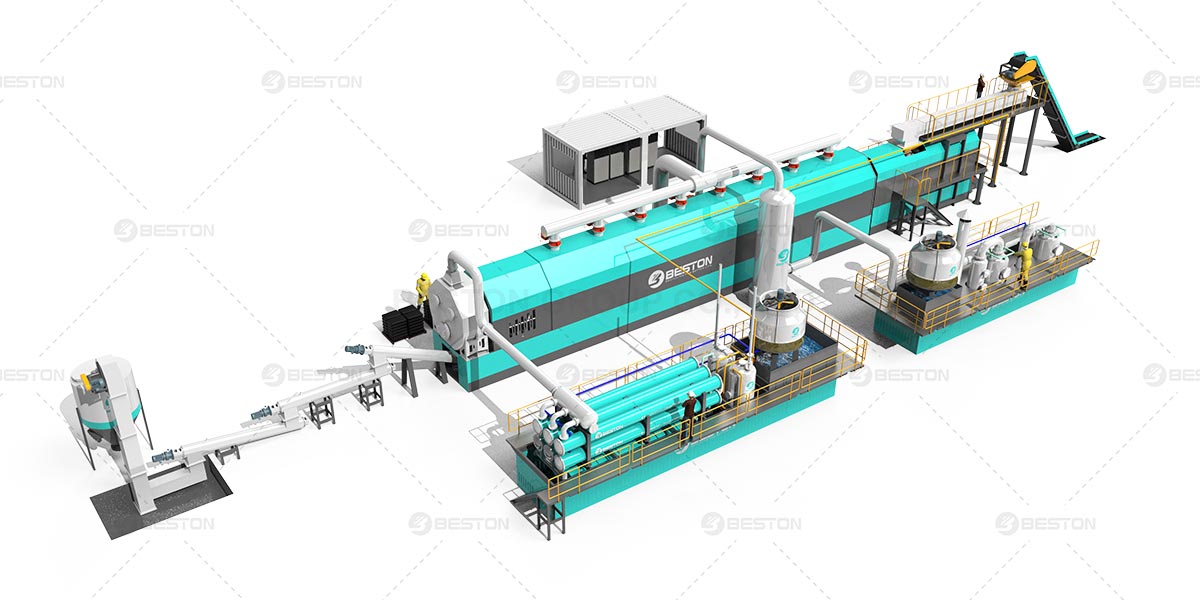

Pyrolysis Reactor:

The prepared plastic waste is fed into a pyrolysis reactor, where it undergoes thermal decomposition at elevated temperatures. The reactor is designed to operate in the absence of oxygen to avoid combustion. The temperature and residence time in the reactor are critical factors that influence the efficiency of the pyrolysis process. Besides, the reactor is the important part of pyrolysis equipment cost.

Condensation and Collection:

As the plastic undergoes pyrolysis, it breaks down into gaseous and liquid hydrocarbons. These products are then cooled and condensed into a liquid form through a condensation system. The liquid products obtained from pyrolysis include pyrolysis oil, which has the potential for various applications.

Gas Treatment:

The gaseous byproducts generated during pyrolysis, such as syngas, are subjected to gas treatment processes. This involves removing impurities and potentially capturing valuable gases for further use. Gas treatment is a crucial step in ensuring the environmental sustainability of the pyrolysis process.

Product Refining:

The liquid products obtained from condensation, particularly pyrolysis oil, undergo further refining processes to enhance their quality and utility. This may involve removing impurities and adjusting the composition of the final product to meet specific requirements.

Benefits of Plastic Pyrolysis:

Waste Reduction:

Plastic pyrolysis contributes to significant waste reduction by converting plastic waste into valuable products. This helps alleviate the burden on landfills and reduces the environmental impact of plastic pollution.

Resource Recovery:

The pyrolysis process allows for the recovery of valuable resources from plastic waste. Pyrolysis oil, obtained as a byproduct, can be used as a fuel source or as a feedstock for the production of chemicals and materials.

Energy Generation:

The syngas produced during plastic pyrolysis can be utilized as a clean energy source. It has the potential to replace conventional fossil fuels, contributing to a more sustainable energy landscape.

Circular Economy:

Plastic pyrolysis aligns with the principles of a circular economy by closing the loop on plastic waste. Instead of a linear approach of disposal, the process transforms plastic into valuable products, promoting a more sustainable and circular use of resources.

Challenges and Considerations:

While plastic pyrolysis holds great promise, it is essential to acknowledge the challenges and considerations associated with its implementation.

Technological Challenges:

Developing and optimizing efficient pyrolysis technologies is a complex task. Researchers and engineers face challenges in achieving high yields, minimizing energy consumption, and addressing the specific characteristics of different types of plastics.

Economic Viability:

The economic viability of plastic pyrolysis is influenced by factors such as initial investment costs, operational expenses, and market demand for the end products. For widespread adoption, it is crucial for the process to be economically competitive with existing waste management methods.

Regulatory Framework:

The implementation of plastic pyrolysis on a large scale requires a supportive regulatory framework. Clear guidelines and standards are needed to ensure the safety, environmental sustainability, and compliance of pyrolysis facilities.

Public Perception:

Public perception plays a significant role in the acceptance of plastic pyrolysis. Educating the public about the benefits and safety measures associated with the process is essential to garner support and address concerns. See the impact of this project in Romania: Pyrolysis Plant in Romania.

Potential Impact on Plastic Waste Crisis:

Reduced Environmental Impact:

By diverting plastic waste from landfills and incineration, plastic pyrolysis reduces the environmental impact of conventional disposal methods. This, in turn, helps mitigate soil and water contamination, as well as the emission of greenhouse gases.

Resource Conservation:

Plastic pyrolysis contributes to resource conservation by recovering valuable materials from plastic waste. This aligns with the principles of a circular economy, where resources are reused, recycled, and repurposed.

Energy Transition:

The use of syngas and pyrolysis oil as alternative energy sources supports the global transition towards cleaner and more sustainable energy. This is particularly crucial in reducing reliance on fossil fuels and mitigating climate change.

Innovation and Research Opportunities:

The development of plastic pyrolysis technologies presents opportunities for innovation and research. Scientists and engineers can explore ways to improve efficiency, explore new feedstocks, and discover novel applications for the products obtained from pyrolysis.

Conclusion:

Plastic pyrolysis emerges as a promising solution to the escalating plastic waste crisis, offering a sustainable way to manage and repurpose plastic waste. While challenges exist, ongoing research, technological advancements, and supportive regulatory frameworks can pave the way for the widespread adoption of plastic pyrolysis. As society strives for a more sustainable future, embracing innovative technologies like plastic pyrolysis becomes imperative in addressing the environmental challenges posed by plastic pollution. Through collective efforts, we can turn the tide on plastic waste and move towards a more circular and environmentally conscious approach to plastic management.